The first photo is what I believe a factory, (dearborn) backhoe frame, a 4 point connection that essentially clamps down on the receiving end of the backhoe, and appears by itself to be a full frame that mounts to both the rear axle housings and further up onto the tractor. Now I am not sure what else the front mounting point entails, is there hardware, brackets, steel rails, like an 1840, 1841 industrial which I believe has that additional steel because its an industrial model, suited for these attachments. Those sherman power diggers and similar certainly appear to be a lot heavier than yours, but that is speculation.

The last photo is of my 850 ford, with a wagner front end loader, it had a backhoe at one time, and the 4 point mount is part of the wagner frame, and or a continuation of it. The wagner is also connected at the front of the tractor through the front axle bolster support to the actual engine block.

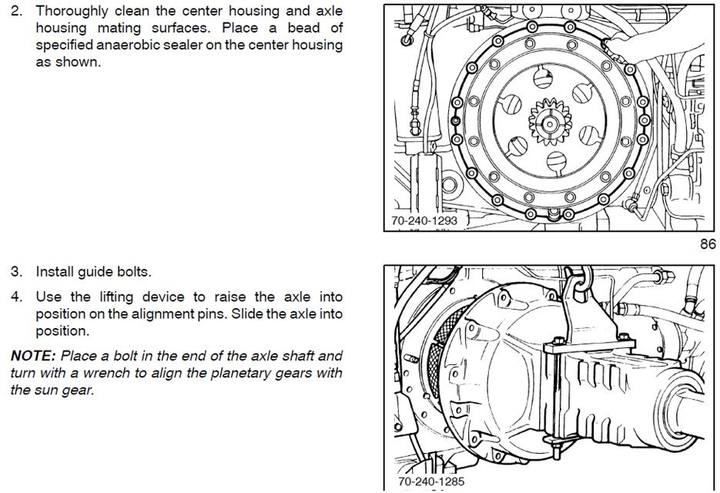

These types of mounts, basically clamp the hoe in the mount and the 2 lower arms are an extension of the wagner loader frame on mine. The top arms are attached further ahead and are orientated to fit over the axle housings and to align with the bottom arms, whereas the backhoe mounting points fit together with these arms and are then clamped down with the use of threaded rod, or like on mine, just the top ends.

Stress points are many on these. On mine, the section of loader frame just ahead of the axle housings, near the foot rest plates is one. Under hard use, shock or impact loads, or exerting heavy break out forces by an abusive operator can and will break the frame if it is not stout enough. Keep in mind, that if the frame is strong enough to resist fatigue and failure, something else, (cast housings) may take that load and fail if not designed for same. On the front of my engine block are repair welds, now that may be from the front end loader, also the cross member under the front mount pump was broke, as was the right hand upright welded connection to the bottom frame member, (below the 2 levers for the loader) Additionally, the part of the rear end, (differential) housing, the ear that projects out with a hole for the top link assembly is fractured on the top side. This tractor is an example of someone who was more than likely abusive. Top link may or may not be related, I don't believe with a 4 point mount its needed. What we need in this post is someone to post photos of one of these assembled, so if anyone has photos of a sherman power digger or similar, maybe they can post the photos, they are not rare, maybe less in numbers now, they were popular in their time period.

Once attached, you have to realize that what you have is marginal as far as the design, there are a lot of heavy forces at work when you think about these. With that in mind, use it accordingly, or be prepared for potential problems. I would also advise that if you need to alter the existing backhoe for mounting purposes, make absolutely sure its done by a competent, experienced, or certified welder that can do the work without compromising the steel. You have to realize that torch cutting, can em-brittle steel, then if welded at the same location, with the forces at work, what has been fabricated could fail, again, give the amount of forces concentrated at the connections. Looking at it, perhaps you just to add mounts to the existing steel, but if there is further or more involved fabrication, it MUST be done correctly.

I won't indulge any discussion about steel fabrication, welding, torch or plasma cutting etc. I'm no expert, but am experienced enough with heavy equipment to know this has to be done correctly, its a structural component that requires lots of strength. I say that to exclude myself from this as it often leads to debate, have at it guys LOL !

I realize this is a 335 industrial model, which was suited for a factory built backhoe and front end loader. The tractor was designed for these attachments, it would be wise to follow what they did, as it was engineered to work, within certain parameters and specifications, its likely your best guideline and if you are not abusive, the end result would likely be fine for trenching, light excavation,(not rock, shale, heavy frost), as well as surface work. What I am saying is don't try and break through rock, frost, pound posts, piles or anything of the like, trust me, the things I have seen abusive or unskilled equipment operators do in the past, it needs to be said LOL!

I think if done right and you take your time, its a worthy endeavor as its just the mount and that's not very complicated at first glance, (well there is always more to these things than meets the eye, but...... LOL !)