I thought I'd do an update on my hay equipment rather than my NH68 only on this post.

My oldest boy was with me and we had a very busy day of it.

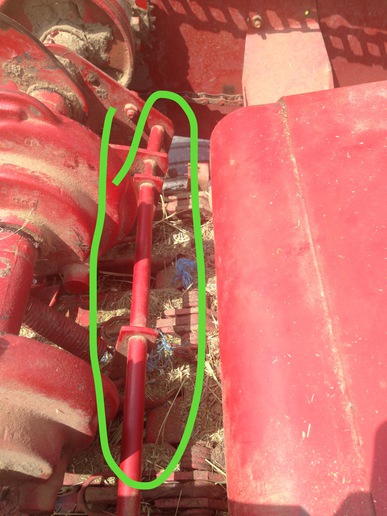

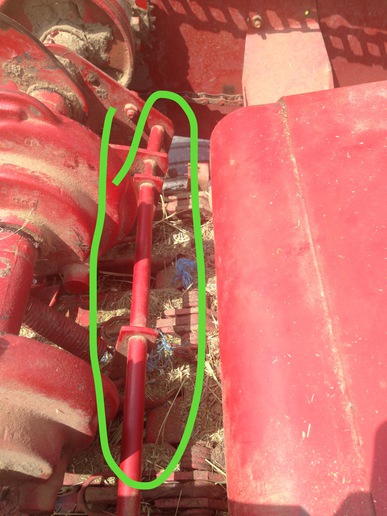

Massey Ferguson MF32 sickle bar mower:

Pulled the knife section out of it today - very easy, once we figured out the knife came out towards the tractor and not the opposite!

The knife bar looks to be in very good shape and most of the sickle sections are fair to good shape. All of them are bottom serrated. The guards, except for two of them (27 in all) look pretty old and though worn, seem to be OK. The ledgers on all of these guards are serrated.

I've read the MF sickle bars are the easiest to attach/detach compared to other makes and I have to admit I like that it pretty much is a - mount to the 3 point hitch and go vs. some funky OEM stabilizer, cable or other arrangement. However, mounting this MF32 has been somewhat a chore. We blocked it up to remove today and that seemed to help a bunch. Any secrets to easily mounting/removing a MF32 from your tractor?

I'd like to give this sickle bar a try over Labor Day holiday weekend, so time is short. I'm going to do a total re-do of this mower over the winter, new guards and knife assy, but in the mean time, what I'd like to do is sharpen the sickle sections, reset the hold downs - so they are doing their job. Where I have concerns are two fold. One is I've got sickle sections that are serrated - running on serrated ledger plates. Second, other than the two newer guards, the old guard's ledger plates, though not bad in shape are dull. Don't know if this is a good idea or not - but what I'm thinking about doing is using an angle grinder or just a big file and grinding what remains of the serrations off the ledger plates such that I'll have smooth, but sharp cornered ledger plates. Over the winter, I'll replace all of the ledgers. The grinding deal would be a short term fix/try.

JD 350 hay rake:

Yesterday we put a new belt on the rake, today we brought it out to the camp and unloaded it from the trailer. Once on the ground, we greased up every zerk and mounted it to the tractor. Nice piece of equipment. Ran the PTO - knock on wood, nothing made loud noises or smoked. I think this rake is field ready. It certainly is a simple designed rake - which I appreciate.

NH68:

Didn't get to spend as much time with the NH68 as I wanted, but I was able to have a look-see at the knotter chain. I took it off and it's pretty well used. If the parts list calls for 63 links, this one had 64. There was no offset link and the bottom line is this chain will be replaced with a new one. While I'm at it, I'll probably replace the chain from the main drive and the pick-up. The chain on the feeder forks looks OK.

Hopefully we'll make more progress next weekend.

Bill

My oldest boy was with me and we had a very busy day of it.

Massey Ferguson MF32 sickle bar mower:

Pulled the knife section out of it today - very easy, once we figured out the knife came out towards the tractor and not the opposite!

The knife bar looks to be in very good shape and most of the sickle sections are fair to good shape. All of them are bottom serrated. The guards, except for two of them (27 in all) look pretty old and though worn, seem to be OK. The ledgers on all of these guards are serrated.

I've read the MF sickle bars are the easiest to attach/detach compared to other makes and I have to admit I like that it pretty much is a - mount to the 3 point hitch and go vs. some funky OEM stabilizer, cable or other arrangement. However, mounting this MF32 has been somewhat a chore. We blocked it up to remove today and that seemed to help a bunch. Any secrets to easily mounting/removing a MF32 from your tractor?

I'd like to give this sickle bar a try over Labor Day holiday weekend, so time is short. I'm going to do a total re-do of this mower over the winter, new guards and knife assy, but in the mean time, what I'd like to do is sharpen the sickle sections, reset the hold downs - so they are doing their job. Where I have concerns are two fold. One is I've got sickle sections that are serrated - running on serrated ledger plates. Second, other than the two newer guards, the old guard's ledger plates, though not bad in shape are dull. Don't know if this is a good idea or not - but what I'm thinking about doing is using an angle grinder or just a big file and grinding what remains of the serrations off the ledger plates such that I'll have smooth, but sharp cornered ledger plates. Over the winter, I'll replace all of the ledgers. The grinding deal would be a short term fix/try.

JD 350 hay rake:

Yesterday we put a new belt on the rake, today we brought it out to the camp and unloaded it from the trailer. Once on the ground, we greased up every zerk and mounted it to the tractor. Nice piece of equipment. Ran the PTO - knock on wood, nothing made loud noises or smoked. I think this rake is field ready. It certainly is a simple designed rake - which I appreciate.

NH68:

Didn't get to spend as much time with the NH68 as I wanted, but I was able to have a look-see at the knotter chain. I took it off and it's pretty well used. If the parts list calls for 63 links, this one had 64. There was no offset link and the bottom line is this chain will be replaced with a new one. While I'm at it, I'll probably replace the chain from the main drive and the pick-up. The chain on the feeder forks looks OK.

Hopefully we'll make more progress next weekend.

Bill