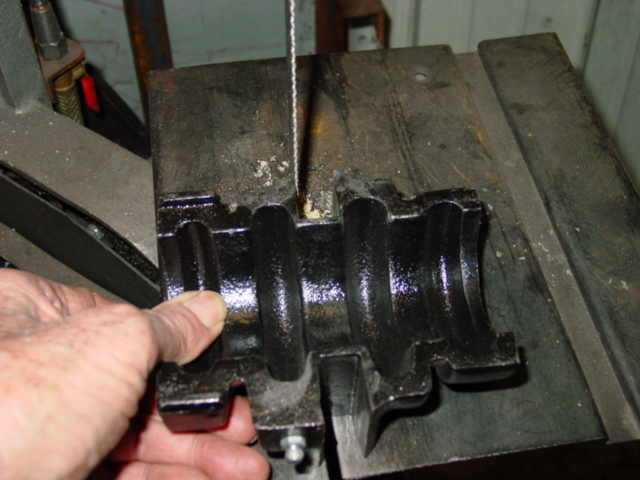

Helping the neighbor take apart his disk harrow he uses for food plots at his hunting club. The disk has some wear/slack in it, and he wants to order new parts (bearings?) for it to tighten it up.

I helped him take it apart this weekend to inspect what needs to be ordered, but we are stumped as to what is worn and needs to be replaced. Here are some pictures.....

I helped him take it apart this weekend to inspect what needs to be ordered, but we are stumped as to what is worn and needs to be replaced. Here are some pictures.....