I am looking at a ford 250 baler to purchase. It is a model#14-80,serial#8691,series504. could anybody tell me the aproximate year and if these were good balers? It appears to have been origanly painted red.I am not familiar with these balers and any information would be appreciated.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Thread starter 63 830

- Start date

chrisinsoky

Member

i just bought one myself, is there a new holland dealer close? there are quite a few parts still availible for these ol balers, i have the parts manual i can make copies for you if need be,

all my old neighbors say they were great balers for the time, pretty simple to work on, easy to set up,

all my old neighbors say they were great balers for the time, pretty simple to work on, easy to set up,

chrisinsoky

Member

i just bought one myself, is there a new holland dealer close? there are quite a few parts still availible for these ol balers, i have the parts manual i can make copies for you if need be,

all my old neighbors say they were great balers for the time, pretty simple to work on, easy to set up,

all my old neighbors say they were great balers for the time, pretty simple to work on, easy to set up,

chrisinsoky

Member

i just bought one myself, is there a new holland dealer close? there are quite a few parts still availible for these ol balers, i have the parts manual i can make copies for you if need be,

all my old neighbors say they were great balers for the time, pretty simple to work on, easy to set up,

all my old neighbors say they were great balers for the time, pretty simple to work on, easy to set up,

chrisinsoky

Member

i just bought one myself, is there a new holland dealer close? there are quite a few parts still availible for these ol balers, i have the parts manual i can make copies for you if need be,

all my old neighbors say they were great balers for the time, pretty simple to work on, easy to set up,

all my old neighbors say they were great balers for the time, pretty simple to work on, easy to set up,

BobH in NH

Member

The 250, and many of Ford's other models of balers, were built by Long Mfg in NC. I bought mine back in 1984 for $500 and ran it until 2 years ago. Nice little baler! I bought it mainly because of its small size and light weight and I only had a '53 Ford 8N to run it with. Probably did at least 1000 bales a year and over 2500 one year. Parts are NOT available, except the bill hooks, clutch discs, and sometimes you can find the pickup fingers. Hay bands are not available. I bought a parts baler early on because mine had knotter issues which we could not seem to correct. Only retired it because the plunger came apart and stuck in the chamber and I did not have time to repair it.

According to the parts manual, S/N 8691 was made prior to latter part of 1958 production as a major revision was made to the sweep arm at that time effective with S/N 10226. Both my operational baler and parts baler are much later models (S/Ns in the 14000s) and have numerous improvements, especially in the PTO overrun and slip clutch assemblies.

Problems: "Orphan" baler, part non-availability, makes banana bales unless properly adjusted and fed, doesn"t handle large heavy windrows well, has wooden runners on bottom and top of plunger which need periodic adjustment or replacement. (I had to make them out of rock maple).

Email me if you have other questions.

Bob

According to the parts manual, S/N 8691 was made prior to latter part of 1958 production as a major revision was made to the sweep arm at that time effective with S/N 10226. Both my operational baler and parts baler are much later models (S/Ns in the 14000s) and have numerous improvements, especially in the PTO overrun and slip clutch assemblies.

Problems: "Orphan" baler, part non-availability, makes banana bales unless properly adjusted and fed, doesn"t handle large heavy windrows well, has wooden runners on bottom and top of plunger which need periodic adjustment or replacement. (I had to make them out of rock maple).

Email me if you have other questions.

Bob

chrisinsoky

Member

long manufactoring was started in 1972 by bill long (http://www.highbeam.com/doc/1G1-7487681.html)

they stop building the 8n in 1952

and you can go to the new holland for website

(http://agriculture.newholland.com/us/en/Pages/homepage.aspx) and go through all the parts still availible through a dealer

they stop building the 8n in 1952

and you can go to the new holland for website

(http://agriculture.newholland.com/us/en/Pages/homepage.aspx) and go through all the parts still availible through a dealer

I'm not familiar with the 250 specifically... I've got a late model 532 that would no doubt employ the same basic design though perhaps updated somewhat. I suspect that this one will compare favorably with any from it's time if it's set up correctly...

The problem ~is~ parts availability and parts cost. You can probably buy most knotter parts and other like things that were outsourced at the time as common components but anything chassis related or specific to that baler you're going to need to make or modify.

That doesn't bother me.... but that's not everyone's cup of tea.

I kinda like the old relic. I've mostly rebuilt mine and as far as I'm concerned it will hold it's own against any of it's competition of the day. I know you won't find little gems like slip clutches on many of the 532's direct competitors. Neither do you find any that run as high a plunger speed...

It's NOT going to bale with a new Hesston or big NH of today but this is 30-50 year old technology too.

Buyer beware.

Rod

The problem ~is~ parts availability and parts cost. You can probably buy most knotter parts and other like things that were outsourced at the time as common components but anything chassis related or specific to that baler you're going to need to make or modify.

That doesn't bother me.... but that's not everyone's cup of tea.

I kinda like the old relic. I've mostly rebuilt mine and as far as I'm concerned it will hold it's own against any of it's competition of the day. I know you won't find little gems like slip clutches on many of the 532's direct competitors. Neither do you find any that run as high a plunger speed...

It's NOT going to bale with a new Hesston or big NH of today but this is 30-50 year old technology too.

Buyer beware.

Rod

chrisinsoky

Member

Tim i may be mistaken but there is a diffence in the 2 (long manufactoring)(and the long tractor company )then again i could be wrong,

i do know that ford produced its own balers in that time period, i am tryin to research the topic now, not havin much luck

i do know that ford produced its own balers in that time period, i am tryin to research the topic now, not havin much luck

Ford 250 baler is a great little baler if set up correctly.In the sping of 1988 I bought one from a gentleman who quite farming.He had pulled it out of a hedgeerow and completely reworked it. I purchased it for $500.That year I did custom baling along with my own.I put 32,000 bales through that baler until the slides in the chamber wore out.I had them replaced and the baler was still going until I sold it.The only other thing I replaced was the chain up to the knotters.If I run across another one I would buy it.I ran mine with a 50HP tractor.

chrisinsoky

Member

what an interestin story about the long company apparntly at one time there was three differnt long companys (1 set of bros in nc, and a company in the ukraine)they went through bank ruptcy, mergers, etc, they weny under pretty quick, came back in the 70s and imported from overseas,

BobH in NH

Member

I have copies of actual Long Mfg advertising showing them selling identical looking balers to the Ford 20, 350, 530, 532 and 542 series balers. Also, when I have purchased parts like bearings, belts, etc from a local bearing supply house, their computer system has the Ford P/Ns (from the Ford Baler Parts Manuals) loaded as Long P/Ns.

BobH in NH

Member

Have also attempted to purchase parts for both my 250 and 532 from the local NH dealer (4 miles from my farm) and found the few that are still available to be exorbantly priced. What shows as available on the website often is not through the dealer's computer system.

If I were going to do much haying I would buy a newer baler with readily available parts. I have switched to round bales so do not have the problem any more.

If I were going to do much haying I would buy a newer baler with readily available parts. I have switched to round bales so do not have the problem any more.

Do you have any other historical/statistical information though?

I can look at a Claas Markant of the same vintage and at a quick glance they also look VERY similar...

A number of years ago I had NH technical do some research on the subject and the answer they came up with at the time was that the baler was Ford's own creation. Certainly they cast some of the major components such as the gearbox as that quite clearly bears FoMoCo in the casting. Might be that Long did the assembly using what was probably largely a Claas design used under licence along with the common north american knotters that were common to Deere Hesston and NH balers of the time...

I do know that if you look at a Markant baler of the day it does employ that exact same feeding mechanism which was rather unique in it's own right.... In fact, aside from the Claas having it's own knotter and a slightly wider/lower cover over the crank, the chassis of the Claas and Ford balers appear identical.

Rod

I can look at a Claas Markant of the same vintage and at a quick glance they also look VERY similar...

A number of years ago I had NH technical do some research on the subject and the answer they came up with at the time was that the baler was Ford's own creation. Certainly they cast some of the major components such as the gearbox as that quite clearly bears FoMoCo in the casting. Might be that Long did the assembly using what was probably largely a Claas design used under licence along with the common north american knotters that were common to Deere Hesston and NH balers of the time...

I do know that if you look at a Markant baler of the day it does employ that exact same feeding mechanism which was rather unique in it's own right.... In fact, aside from the Claas having it's own knotter and a slightly wider/lower cover over the crank, the chassis of the Claas and Ford balers appear identical.

Rod

BobH in NH

Member

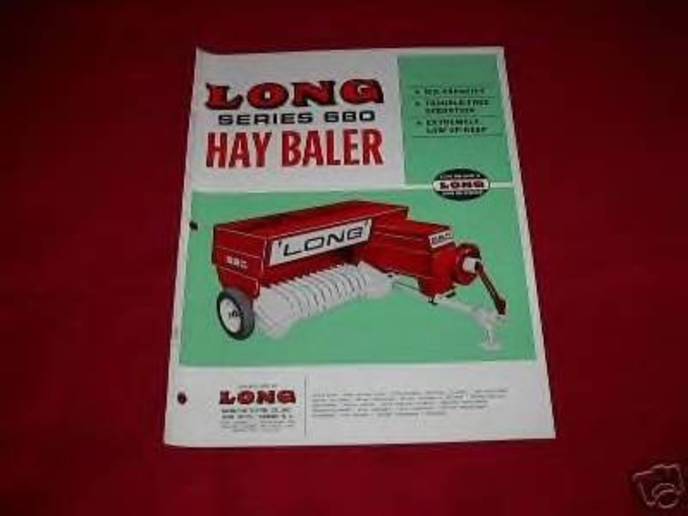

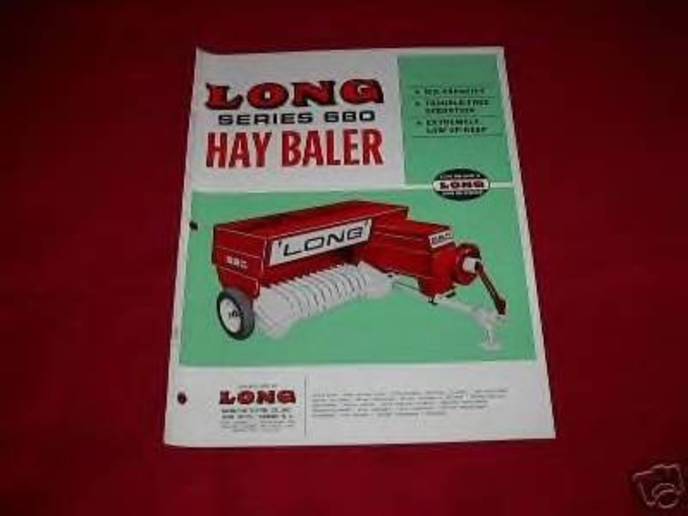

I am associated with a Ford Brand Balers user group on the web. Members freely attempt to assist other Ford Baler users with problems. Following are some extracts from an email exchange between active members on this topic, plus a jpeg file of the cover of a Long Baler Sales Brochure. I believe that the member providing this information is in NC area and is well versed on Ford Balers.

"What you have found is a 540 formerly the 350 that was painted blue when the 250 was replaced by the 530 and Ford took the hay line blue. The 150 became the 520, the 250 was replaced by the 530, and the 350 became the 540. This is the first one I have ever heard of being spotted in the wild. The 250 and 530 were the majority of production volume. The 150/520 was slated for the small farmer with small tractors and made a smaller bale 14x16 if my memory serves me right. The 350/540 was the super heavy duty for the contract operator and was priced considerably higher than the 250/530 without much performance improvement.

JD, NH and Ford all sourced their knotter assemblies from a German company named Rasspe. I have spoken to this company and confirmed this. So several parts will directly replace or can be modified to work in our balers. Gary had a series of pictures comparing NH billhooks to the new set of Fords that he had and other than a slight angle difference, there was no difference. Case obviously wants to drop support for these old balers and get them out of the system.

As for Long. Yes, they absolutely designed and built the 150, 250 and 350 and later designed the 530 and sold the design to Ford and they had it manufactured somewhere for them.

Long also sold this baler for some period of time under their own brand. I have literature from a Ford dealer to his employees about Long coming to do training on the Long/Ford balers in the late 40"s, so they had a long relationship in the hay equipment arena....."

I am also uploading a jpeg image of the Long version of the Ford 350.

Hope this information answers some of your questions.

Bob H in NH

"What you have found is a 540 formerly the 350 that was painted blue when the 250 was replaced by the 530 and Ford took the hay line blue. The 150 became the 520, the 250 was replaced by the 530, and the 350 became the 540. This is the first one I have ever heard of being spotted in the wild. The 250 and 530 were the majority of production volume. The 150/520 was slated for the small farmer with small tractors and made a smaller bale 14x16 if my memory serves me right. The 350/540 was the super heavy duty for the contract operator and was priced considerably higher than the 250/530 without much performance improvement.

JD, NH and Ford all sourced their knotter assemblies from a German company named Rasspe. I have spoken to this company and confirmed this. So several parts will directly replace or can be modified to work in our balers. Gary had a series of pictures comparing NH billhooks to the new set of Fords that he had and other than a slight angle difference, there was no difference. Case obviously wants to drop support for these old balers and get them out of the system.

As for Long. Yes, they absolutely designed and built the 150, 250 and 350 and later designed the 530 and sold the design to Ford and they had it manufactured somewhere for them.

Long also sold this baler for some period of time under their own brand. I have literature from a Ford dealer to his employees about Long coming to do training on the Long/Ford balers in the late 40"s, so they had a long relationship in the hay equipment arena....."

I am also uploading a jpeg image of the Long version of the Ford 350.

Hope this information answers some of your questions.

Bob H in NH

Farmallhal

Well-known Member

Bob, I don't have a dog in this fight but this is truly the kind of support that occurs on occassion of this forum. You are to be commended for jumping in and taking the time to give someone searching for tidbits of some level of info with some real in-depth support. I see this nemerous times on this site and I believe that is one of the main reason I have such an enjoyment for this old tractor and implement restoration activities I'm involved in and try to support. Thanks for your assistance to these folks with the need for this level of information, Hal.

BobH in NH

Member

Thanks for the kind words. I look at this and other forums as opportunities to learn, share information, problem solve, and help others with problems or questions. I am sure I have received a lot more assistance and information from people than I have been able to give back to others!

BobH in NH

Member

Good info!!! Thanks. How expensive???? When I was working on the knotters on the 250 back in '84 or '85, we tried a new bill hook on the side that frequently mistied. At that time the billhook was in excess of $95.00. Bought my entire parts 250 for $300 and it had just been overhauled. Apparently they set up the knife clearance wrong and chipped a tooth in the gearbox when it locked up.

Had to replace the flywheel hub on the 532 two years ago. I checked into getting new clutch discs for both the flywheel and the PTO slip clutch and decided against it. If I remember they were priced over $45 per disc. One of the two were identical to those on the 250 and I had some serviceable used ones. They had more than trippled in price in 10 years!

Now I am starting to recondition the T500 Ejector that came with the baler. Can't wait to see how expensive the bearings and variable speed pulley will be! At least I also have the parts manual for th ejector.

Had to replace the flywheel hub on the 532 two years ago. I checked into getting new clutch discs for both the flywheel and the PTO slip clutch and decided against it. If I remember they were priced over $45 per disc. One of the two were identical to those on the 250 and I had some serviceable used ones. They had more than trippled in price in 10 years!

Now I am starting to recondition the T500 Ejector that came with the baler. Can't wait to see how expensive the bearings and variable speed pulley will be! At least I also have the parts manual for th ejector.

I forget. The hooks are in the 80-100 buck range tho (each). One way to look at it... if you need hooks for a NH, Deere, Hesston or whatever... they're all going to be in that range.

The slip clutch discs are about the same price today. I need a set right now. Probably going to pull it apart tomorrow actually. Need to measure them up for a cross to off the shelf Weasler stuff. That should fall in around 10 bucks each...

The ORC also blew up in mine last fall. I just welded a scab of metal from the hub to the yolk with NiRod. I think it will hold... Plan is to add an ORC yolk on the drive end and it should then be good to go. No way I was paying over 400 bucks for an ORC unit for the OEM setup though they are available.

If I can get that sorted out to my satisfaction then I'm going to rebuild the pickup to a more modern spec using Claas or NH supersweep fingers and strippers.

The main problem with those balers was their inability to feed in some crops. If the devil would feed it will bang out 400/hour pretty steady.

It's quite capable of shaming the small NH balers in capacity if it's set up correctly...

Rod

The slip clutch discs are about the same price today. I need a set right now. Probably going to pull it apart tomorrow actually. Need to measure them up for a cross to off the shelf Weasler stuff. That should fall in around 10 bucks each...

The ORC also blew up in mine last fall. I just welded a scab of metal from the hub to the yolk with NiRod. I think it will hold... Plan is to add an ORC yolk on the drive end and it should then be good to go. No way I was paying over 400 bucks for an ORC unit for the OEM setup though they are available.

If I can get that sorted out to my satisfaction then I'm going to rebuild the pickup to a more modern spec using Claas or NH supersweep fingers and strippers.

The main problem with those balers was their inability to feed in some crops. If the devil would feed it will bang out 400/hour pretty steady.

It's quite capable of shaming the small NH balers in capacity if it's set up correctly...

Rod

+-We had one until last year. The knives were straight up and down so the tried to cut the hay all at once. Dad took one knife out and replaced it with a wedge shaped knife so it cut with a sissors action. Raised the capacity a lot. Good baler. Made nice square bales and don't recall it ever missing except maybe when switching balls of twine.

Similar threads

We sell tractor parts! We have the parts you need to repair your tractor - the right parts. Our low prices and years of research make us your best choice when you need parts. Shop Online Today.

Copyright © 1997-2024 Yesterday's Tractor Co.

All Rights Reserved. Reproduction of any part of this website, including design and content, without written permission is strictly prohibited. Trade Marks and Trade Names contained and used in this Website are those of others, and are used in this Website in a descriptive sense to refer to the products of others. Use of this Web site constitutes acceptance of our User Agreement and Privacy Policy TRADEMARK DISCLAIMER: Tradenames and Trademarks referred to within Yesterday's Tractor Co. products and within the Yesterday's Tractor Co. websites are the property of their respective trademark holders. None of these trademark holders are affiliated with Yesterday's Tractor Co., our products, or our website nor are we sponsored by them. John Deere and its logos are the registered trademarks of the John Deere Corporation. Agco, Agco Allis, White, Massey Ferguson and their logos are the registered trademarks of AGCO Corporation. Case, Case-IH, Farmall, International Harvester, New Holland and their logos are registered trademarks of CNH Global N.V.

Yesterday's Tractors - Antique Tractor Headquarters

Website Accessibility Policy