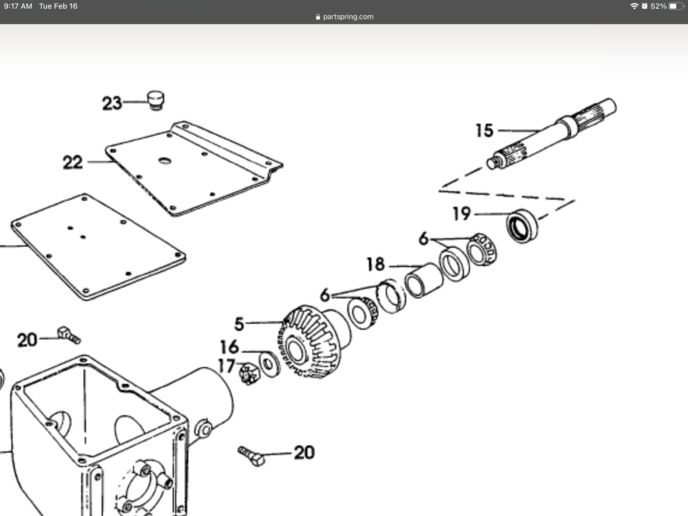

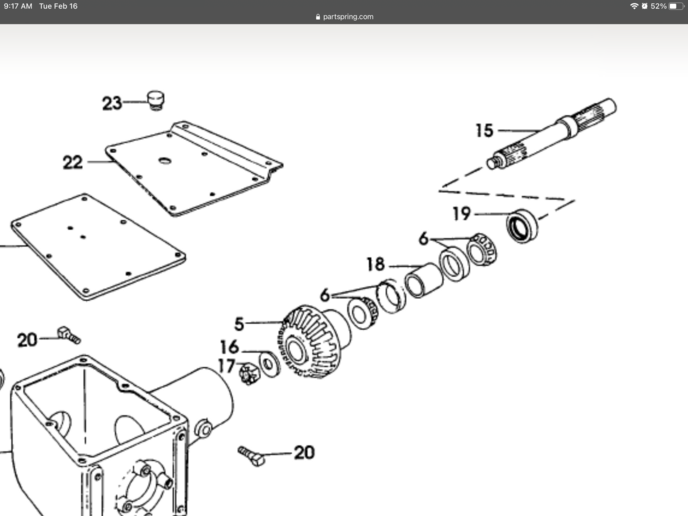

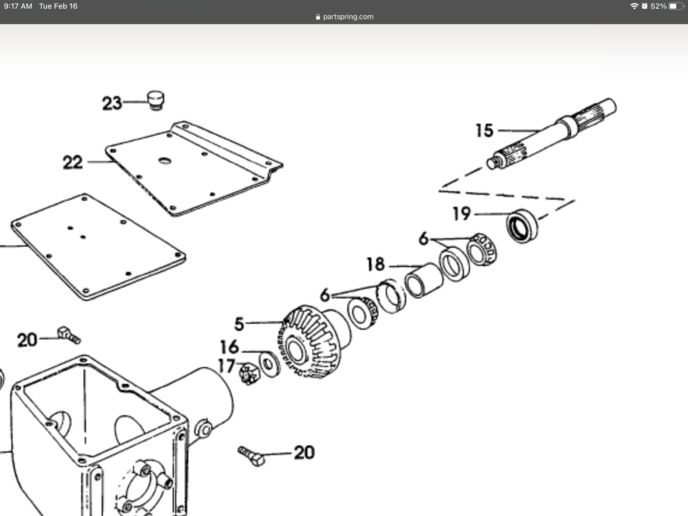

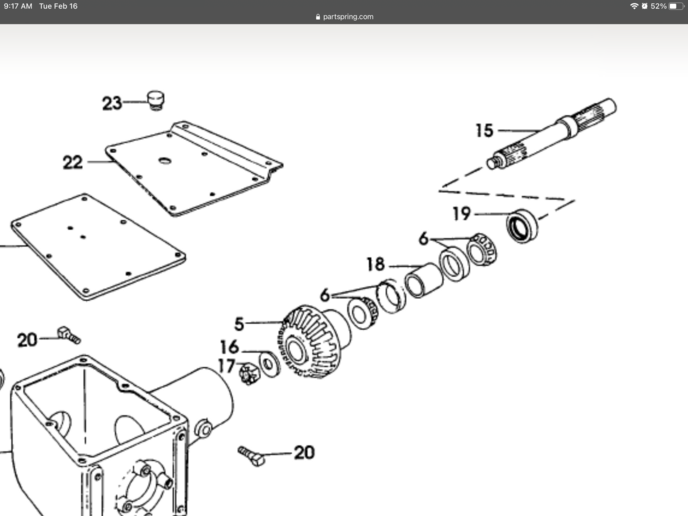

This project started out just to replace oil seal (19). In the process of pulling out input shaft (15) the outer bearing (6) came apart. The shaft was pretty snug on the way out and apparently the pulling knocked the roller bearing cage loose. I did back off on both bolts (20) as the service manual says. Maybe 1/4-1/2. Anyway I ended up having to cut the outer bearing inner race off the shaft. I could not get it to budge with heat. Now I am putting the replacement bearing back on but it sure is tight from the start. I was going to start tapping the other end of the shaft on a table to get the bearing to slide down but though Id ask here to see the experience of others. Thanks.