I had several posts looking for advice on feeding / plugging issues on my new to me Gleaner M2.

Well I finally finished my soybean harvest and I learned several things.

For anyone having problem feeding short beans, and feeding in general along with or without plugging the feeder beater.. Or just plugging the feeder beater in general here is what I did.

I took apart the feeder beater slip clutch....

I ended up replacing the jaw set even though mine didn't look terribly worn. After comparing mine to a new set I figured I would try a new set and what a difference it made!! I inspected the springs and reassembled with a new lock collar on the bearing behind the beater drive sprocket.

After replacing the jaws ( and setting the proper clearance) I never once plugged the beater.

Second, which I think made the biggest difference.....

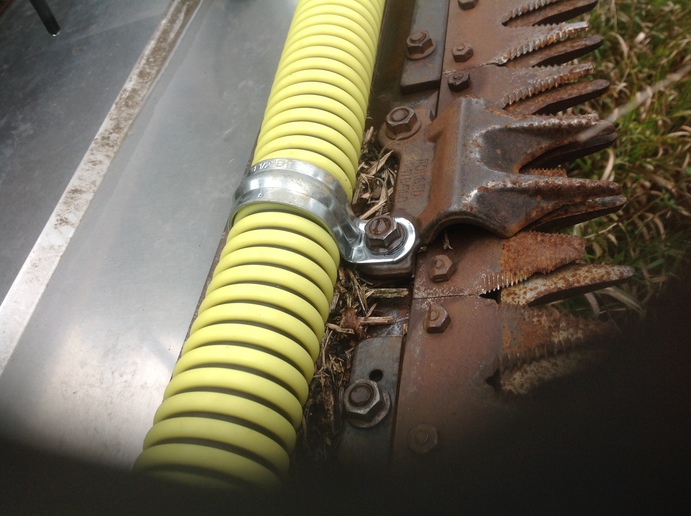

I mounted a piece of 3" flexible corrugated field tile behind the cutter bar on my Series 3 head.

This made the head feed 1,000% better. The the beans fell over the tile and the auger picked them up quickly. Most of the beans I cut with this setup were longer, but I did cut some short beans and they fed very well.

The combine ran very smooth after I installed the tile behind the cutter bar, it seriously ran so smooth that I had to keep looking behind me and make sure beans were running into the bin.

The combine operated amazing after these modifications and I hope that someone can attain some help from my post!

Well I finally finished my soybean harvest and I learned several things.

For anyone having problem feeding short beans, and feeding in general along with or without plugging the feeder beater.. Or just plugging the feeder beater in general here is what I did.

I took apart the feeder beater slip clutch....

I ended up replacing the jaw set even though mine didn't look terribly worn. After comparing mine to a new set I figured I would try a new set and what a difference it made!! I inspected the springs and reassembled with a new lock collar on the bearing behind the beater drive sprocket.

After replacing the jaws ( and setting the proper clearance) I never once plugged the beater.

Second, which I think made the biggest difference.....

I mounted a piece of 3" flexible corrugated field tile behind the cutter bar on my Series 3 head.

This made the head feed 1,000% better. The the beans fell over the tile and the auger picked them up quickly. Most of the beans I cut with this setup were longer, but I did cut some short beans and they fed very well.

The combine ran very smooth after I installed the tile behind the cutter bar, it seriously ran so smooth that I had to keep looking behind me and make sure beans were running into the bin.

The combine operated amazing after these modifications and I hope that someone can attain some help from my post!