MNfarmboy83

Member

Hey guys, I need some help. I have never combined corn before. I have always picked it and ground for our calves. This year we have a good problem, to much corn! Our crib is full and so are our gravity boxes and there is still corn in the field.

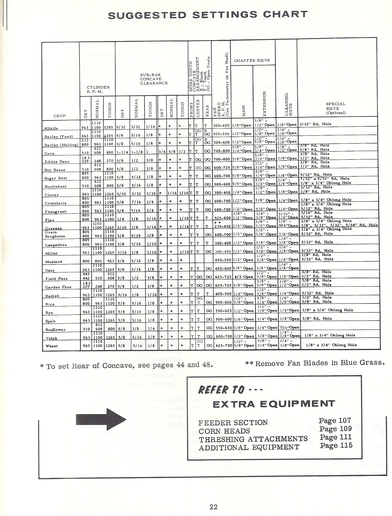

I bought a 2 row head for my 960 case combine late summer and did some work for a neighbor in trade for a corn storage bin. I don't have a manual for the combine and was not planning on combining any corn this year. Now I would like to get the corn off the field and was wondering what, if any, adjustments need to be made to the combine. I can see how the grain pick up head comes off and the corn head goes on but are there adjustments to be made to the combine itself?

Thanks in advance for any help, it is really appreciated! Mike

I bought a 2 row head for my 960 case combine late summer and did some work for a neighbor in trade for a corn storage bin. I don't have a manual for the combine and was not planning on combining any corn this year. Now I would like to get the corn off the field and was wondering what, if any, adjustments need to be made to the combine. I can see how the grain pick up head comes off and the corn head goes on but are there adjustments to be made to the combine itself?

Thanks in advance for any help, it is really appreciated! Mike