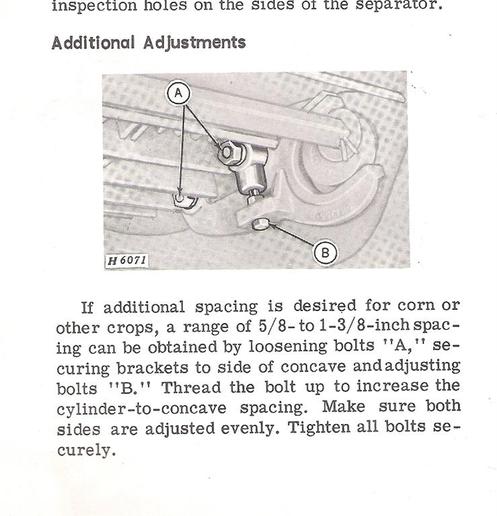

I posted recently regarding the amount of corn being cracked by the JD 45 combine that I bought and tried out for the first time. Some of you suggested that I increase the cylinder/concave clearance and reduce cylinder rpm. I did so and harvested some more corn. There is still a small amount of cracked kernels visible, perhaps nothing more than can be normally expected. Most cobs are whole now or broken in two pieces but not split/crushed as before. The operator manual says to set cylinder/clearance for corn at 1-1/4 inch at front and 5/8 at rear. I could only get 1 inch at front. Just above is a picture and text from manual showing how to get more spacing at the front of the concave. I assume that this adjustment can be made only by removing corn head, or is it possible with corn head attached? I am running cylinder at 386 rpm , down from 536 before. I could get another sprocket and reduce speed farther to 325 rpm. Would this be any advantage ? Corn is less than 12.5% moisture.

Also above are a few pictures of the combine and shelled corn in the tank.

Also above are a few pictures of the combine and shelled corn in the tank.