BANDITFARMER

Well-known Member

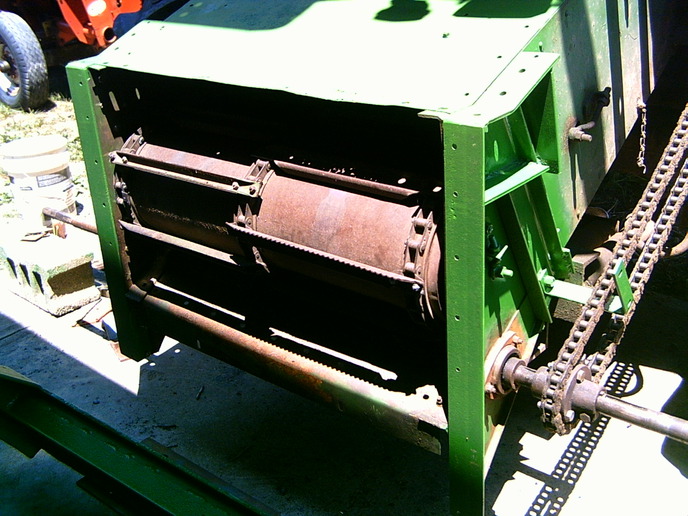

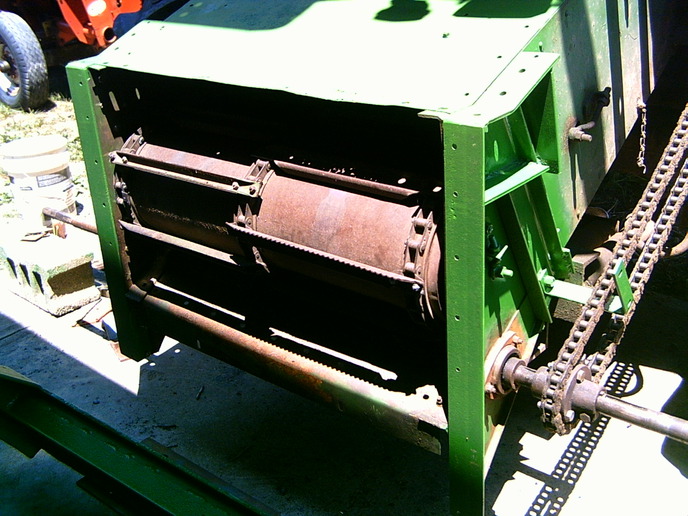

I figuared after the phone calls and emails about how I did this change over for the AC corn head on the JD 95 I would make it easer to see how I did. After taking the JD face plate off I changed the 1 1/2x2 inch angle to a 3x3 angle and drilled it to fit the JD face plate and the feeder house with a few more bolts added for strenth. I added a 4 inch chanel from the top down to ware the hydrolic cylinder hooks up and a piece of 3x1/4 flat band bent to fit on the side of the feeder house for the AC adapter to bolt to. The AC adapter is bolted to the top of the feeder house and the extra suport I added to it. I did double the lift cylinders and now it will lift the corn head at an idle. To drive the corn head I added a 16 tooth weld-a-sproket to the drive side behind the hub that drives the shaft, On the other side I cut a key way to the shaft and added the same 16 tooth sproket to that side for the drive. Anyway to go back to the JD face plate all I have to do is unbolt the top AC adapter and bolt the face plate back on and put the JD head on and we are ready to go. As you can see in the pictures nothing interfears with the JD face plate when I put it back on so the extra reinforcement are tucked in just right. I gave it a paint job as I put it back togeather, Not to bad lookin. Now dad thinks I need to paint the whole combine! I told him I'll do it like Johnny Cash did ONE PIECE AT A TIME! Bandit