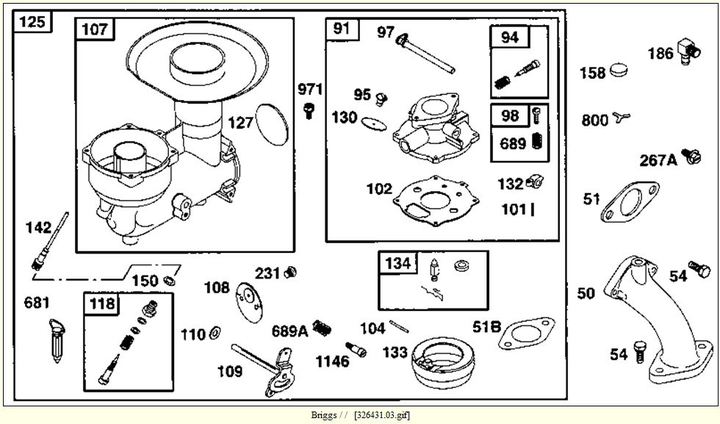

Guys, Looking for some help. I rebuilt my carb on a Simplicity 3416, Briggs engine. The carb is a 326431. The rebuild went great and the tractor now runs well, the problem I now have, that I didn"t have before, is that when I shut the engine off, gas drips out of the "vent" port on the bottom of the carb housing. Not sure how this could NOT have leaked before, but it is leaking now. This is really annoying, any thoughts on why this is leaking? My 3314 with the same carb doesn"t have this problem. The only thing I can come up with is that there is a part, "Washer, Fiber Viton Seat" in the carb kit I didn"t install. I don"t know where it goes, didn"t take one out during the rebuild, could this allow the vent to leak?

Thanks

Thanks