Anonymous-0

Well-known Member

Hello all,

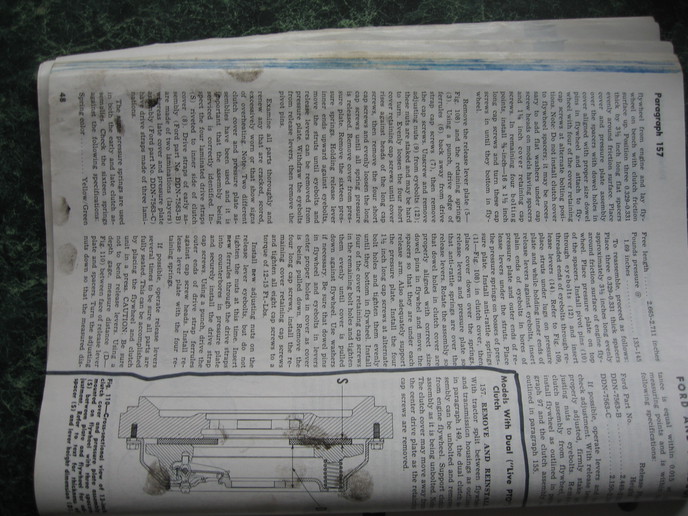

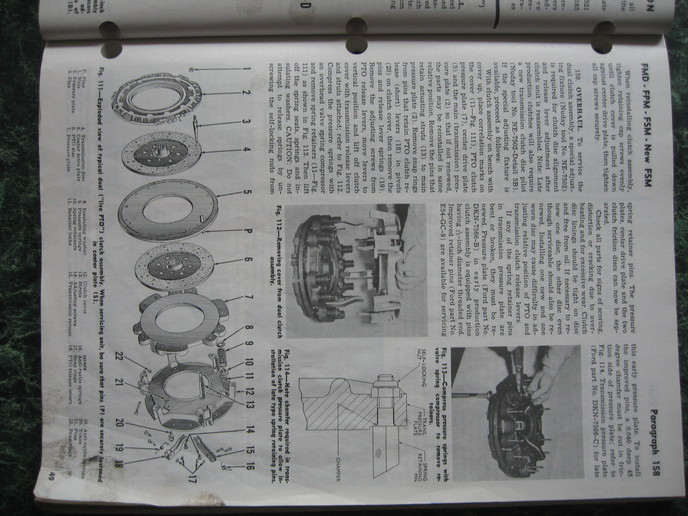

Still trying to put my '64 SM back together to complete a rebuild project I started in '09. I have not figured out how the dbl clutch "short" lever springs go back. I know one finger of the spring has a 90 degree bend to the left and then a 90 degree bend stright into a hole in the lever. The other end seems to tuck into the opening of the aluminum cover, I can see the old marks and I do remember taking them out, but for the life of me, they don't seem to fit properly. As I try to line up both holes( spring and lever) and push the pin through, the stright tail of the spring seems too long to tuck down into the opening in the cover plate. Any advice is much appreciated on that subject. One other thing while I am here, I have an engine rebuild kit. the machinest that worked on my block had to mill the top down because it was warped. I bought an all copper head gasket beside the one that comes with the engine kit. Is the copper better to use? How in the heck does it seal? I am also afriad the head will need milling when I get it to the shop. I hope the valves don't hit the pistons after all this. Thanks guys!

Kerry

Still trying to put my '64 SM back together to complete a rebuild project I started in '09. I have not figured out how the dbl clutch "short" lever springs go back. I know one finger of the spring has a 90 degree bend to the left and then a 90 degree bend stright into a hole in the lever. The other end seems to tuck into the opening of the aluminum cover, I can see the old marks and I do remember taking them out, but for the life of me, they don't seem to fit properly. As I try to line up both holes( spring and lever) and push the pin through, the stright tail of the spring seems too long to tuck down into the opening in the cover plate. Any advice is much appreciated on that subject. One other thing while I am here, I have an engine rebuild kit. the machinest that worked on my block had to mill the top down because it was warped. I bought an all copper head gasket beside the one that comes with the engine kit. Is the copper better to use? How in the heck does it seal? I am also afriad the head will need milling when I get it to the shop. I hope the valves don't hit the pistons after all this. Thanks guys!

Kerry