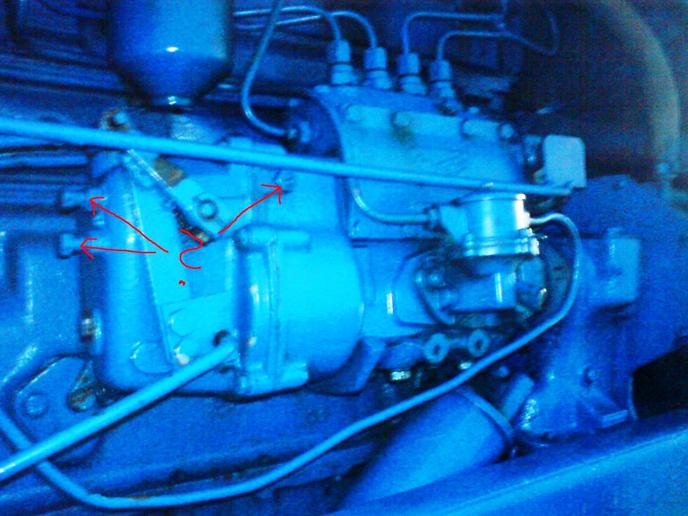

Hello to all, I changed the SIMMS injection pump on my Super Major, model year 1963. After changing the pump the engine had low rpm. Does anybody know how to increase the fuel flow. Which is the right screw for giving the engine more fuel in order to reach the neccessary rpm. For your information, there are two hexagon screws fittet in vertical position on the left hand side of the pump and both are secured with a nut and a locking wire. But I could find another screw (slotted screw) also secured with a nut located close to the left of outcomming 4ea fuel pipes.

Thank you in advance for your help and maybe sorry for writing in an incorrect English language, because I am from Germany an found this good forum - thank goodness - via the internet.

Regards

Florian

Thank you in advance for your help and maybe sorry for writing in an incorrect English language, because I am from Germany an found this good forum - thank goodness - via the internet.

Regards

Florian