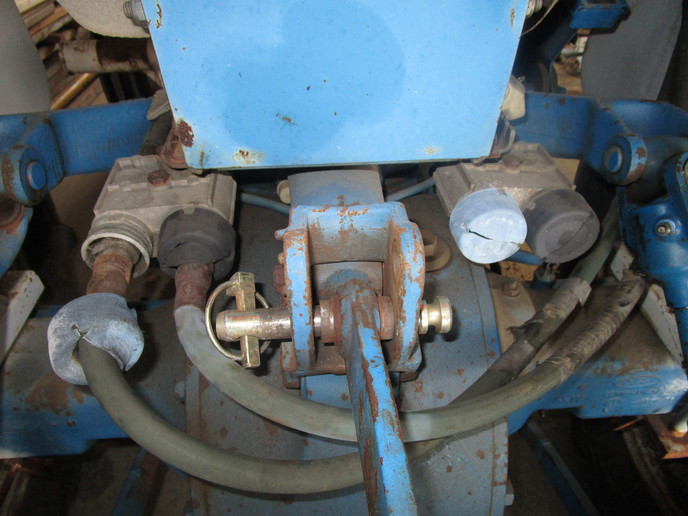

So the spool valve on my dunham lehr 22 loader failed (left spool stuck in) and hydraulic shop said they cannot repair. ordered a cross BA2 F2 with float, should be here next week. since i've had the system open now, does anybody any words of wisdom on installing the new valve, bleeding, and making sure i don't get another valve failure? '78 ford 3600

the last valve failed about 10 minutes after remounting the loader after having it off for sickle mowing the fields.

the last valve failed about 10 minutes after remounting the loader after having it off for sickle mowing the fields.