Fairtax4me

New User

Hi guys, posted this question on another forum and was directed here with the hopes that someone here may have some good advice!

We (the company I work for) have a 91 Ford 4630 that I'm trying to sort out a mostly annoying issue on.

The tractor has a Ford 7209 FEL.

Double spool remote selector under the seat, with two sets of rear hydraulic ports.

The FEL is connected to one set of those ports, The other is empty.

Issue is, I can only use either the 3pt lift OR the FEL, depending on the selection of the remote. Id like to change this so that the 3pt and FEL can be used at the same time without having to reach down and switch back and forth on the selector.

Obviously we wont be moving control levers for both at the exact same time, but quite often we need to be able to operate the FEL, then the 3pt, and back again.

Second issue with having the FEL connected to the remote selector is the pressure feedback from the FEL occasionally kicks the remote selector back to center position. So trying to lift or tilt the bucket, then all of a sudden it just stops moving, have to reach down and push the selector lever back into position.

From what I understand its normal for the selector to operate this way. What I don't understand is why the FEL is hooked to the selector, rather than having is own supply separate from the remote selectors?

We have another older ford tractor that has a Woods FEL, single spool selector and singe set of rear hydraulic ports. And that tractor we can use the FEL and 3pt at the same time no problem. So I know its possible to have them work like this. I just don't know how to achieve that on or bigger tractor.

The only major difference I can see between the two is that the older tractor has a block of some sort under the remote selector. The hoses for the FEL on that one are connected to the block. I'll try to post up a picture of it soon. I think I need another of those blocks to make this work properly, I just have no clue what its called and can't find anything like it in NH/Ford parts diagrams.

In case anyone is wondering, I'm replacing the control valve for the FEL, and the supply/return lines for it, which is why I'd like to sort out the selector issue while I have things apart.

Thanks for any help!

We (the company I work for) have a 91 Ford 4630 that I'm trying to sort out a mostly annoying issue on.

The tractor has a Ford 7209 FEL.

Double spool remote selector under the seat, with two sets of rear hydraulic ports.

The FEL is connected to one set of those ports, The other is empty.

Issue is, I can only use either the 3pt lift OR the FEL, depending on the selection of the remote. Id like to change this so that the 3pt and FEL can be used at the same time without having to reach down and switch back and forth on the selector.

Obviously we wont be moving control levers for both at the exact same time, but quite often we need to be able to operate the FEL, then the 3pt, and back again.

Second issue with having the FEL connected to the remote selector is the pressure feedback from the FEL occasionally kicks the remote selector back to center position. So trying to lift or tilt the bucket, then all of a sudden it just stops moving, have to reach down and push the selector lever back into position.

From what I understand its normal for the selector to operate this way. What I don't understand is why the FEL is hooked to the selector, rather than having is own supply separate from the remote selectors?

We have another older ford tractor that has a Woods FEL, single spool selector and singe set of rear hydraulic ports. And that tractor we can use the FEL and 3pt at the same time no problem. So I know its possible to have them work like this. I just don't know how to achieve that on or bigger tractor.

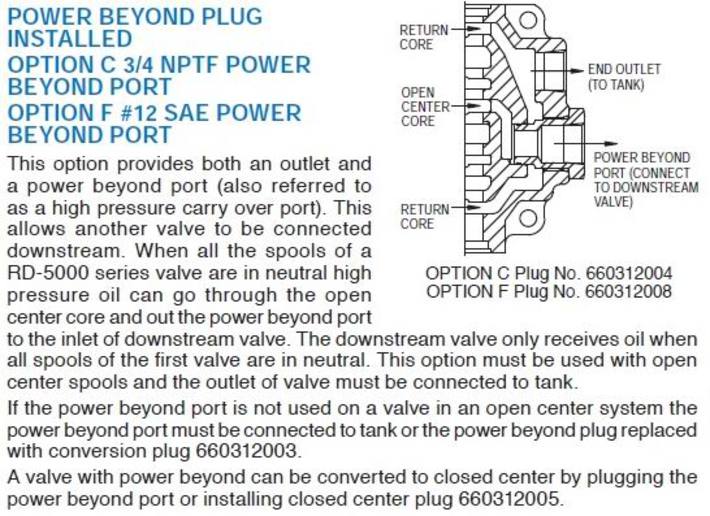

The only major difference I can see between the two is that the older tractor has a block of some sort under the remote selector. The hoses for the FEL on that one are connected to the block. I'll try to post up a picture of it soon. I think I need another of those blocks to make this work properly, I just have no clue what its called and can't find anything like it in NH/Ford parts diagrams.

In case anyone is wondering, I'm replacing the control valve for the FEL, and the supply/return lines for it, which is why I'd like to sort out the selector issue while I have things apart.

Thanks for any help!