Fred Werring

Well-known Member

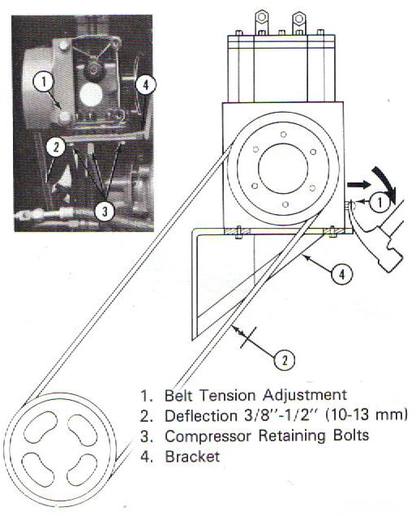

So the previous owner said it liked to throw the AC belt. See post below

Liked the idea by matt from Oz about welding a plate to the front of the mounting plate (had the advantage of being cheap), to tension the pulley.

The compressor was all the way out at the end of the adjustment slots, went to loosen the bolts, started losing refrigerant and oil. Great.

So the I went with the story by juniur...held the new correct size belt on the pulley with a wood hammer handle while daughter bumped the engine, and rolled it on.

Boy is it tight

Probably too tight, but at this point the compressor needs rebuilt (or at least a new bottom gasket), so I'd have to take it off and recharge anyway, so why not?

Anyway, baled about 6 hours with it, belt hasn't come off yet. It's stretched a little, but still plenty tight.

And I'm baling hay in cool dust free air. I could get used to this.

Pic of my new to me 40 year old tractor with the baler. When I first got the baler 20 years ago, I was pulling it with a 5000 (it was all that tractor wanted), and then a Massey 398, the baler looked so big behind those tractors. Not so much behind this one.

thanks for the help

Fred

Original post

Liked the idea by matt from Oz about welding a plate to the front of the mounting plate (had the advantage of being cheap), to tension the pulley.

The compressor was all the way out at the end of the adjustment slots, went to loosen the bolts, started losing refrigerant and oil. Great.

So the I went with the story by juniur...held the new correct size belt on the pulley with a wood hammer handle while daughter bumped the engine, and rolled it on.

Boy is it tight

Probably too tight, but at this point the compressor needs rebuilt (or at least a new bottom gasket), so I'd have to take it off and recharge anyway, so why not?

Anyway, baled about 6 hours with it, belt hasn't come off yet. It's stretched a little, but still plenty tight.

And I'm baling hay in cool dust free air. I could get used to this.

Pic of my new to me 40 year old tractor with the baler. When I first got the baler 20 years ago, I was pulling it with a 5000 (it was all that tractor wanted), and then a Massey 398, the baler looked so big behind those tractors. Not so much behind this one.

thanks for the help

Fred

Original post