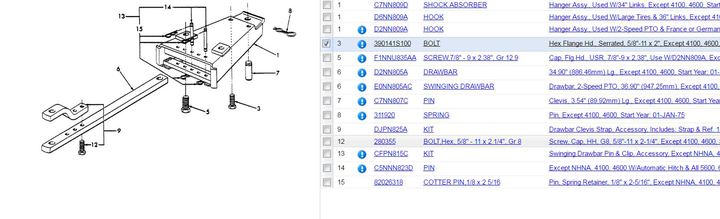

The drawbar bracket bolts got loose. The front pair (?5/8"-11) threads are gone on 1/3 of the tapped hole. The grade bolt is 12.9. My plan is to go to grade 8 bolts that are longer to get up into the other 2/3 of the threads still present. Also going to use Nord-Lock washers. Also going to replace the rear pair ?7/8"-9 with longer bolts.

Anyone else had this problem? If yes, then how did you repair?

Considering using helicoil to repair, but thought I'd try this other method first. I've had good luck with this method on loader brackets on the bell housing.

Thanks

Anyone else had this problem? If yes, then how did you repair?

Considering using helicoil to repair, but thought I'd try this other method first. I've had good luck with this method on loader brackets on the bell housing.

Thanks