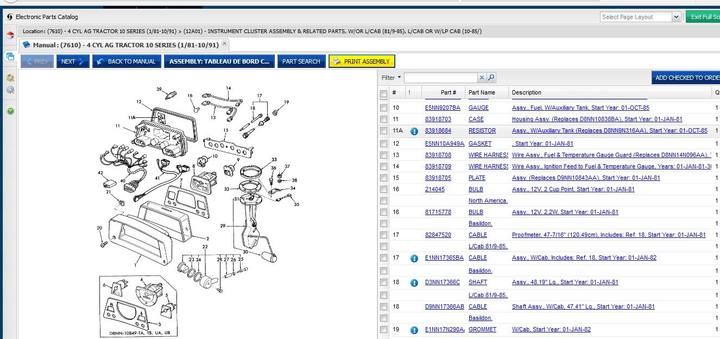

Our 7610 has dual fuel tanks and right now the

fuel gauge and temp gauge don't work quite

right (temp gauge) or at all (fuel gauge). I

am guessing the problem with the fuel gauge is

because it is an aftermarket dash that isn't

designed for dual tanks. My question is if I

buy another dash cluster for it, can I buy the

one made for a single tank and only hook up the

aux tank fuel level sender, since it will read

full until the top tank is empty and starts to

drop the level in the lower tank, which is all

I need to know to know if I am going to run

empty. New holland wants around $600 for a

whole new dash assembly with the dual tank fuel

gauge, or I could buy one for a single tank and

replace the gauge with a dual tank fuel gauge

for a little over half that. However, you can

buy the aftermarket clusters for about $100.

Also, is there anyone that makes wiring

harnesses for these tractors outside of NH?

They want about $1000 for the main harness.

Hurst

fuel gauge and temp gauge don't work quite

right (temp gauge) or at all (fuel gauge). I

am guessing the problem with the fuel gauge is

because it is an aftermarket dash that isn't

designed for dual tanks. My question is if I

buy another dash cluster for it, can I buy the

one made for a single tank and only hook up the

aux tank fuel level sender, since it will read

full until the top tank is empty and starts to

drop the level in the lower tank, which is all

I need to know to know if I am going to run

empty. New holland wants around $600 for a

whole new dash assembly with the dual tank fuel

gauge, or I could buy one for a single tank and

replace the gauge with a dual tank fuel gauge

for a little over half that. However, you can

buy the aftermarket clusters for about $100.

Also, is there anyone that makes wiring

harnesses for these tractors outside of NH?

They want about $1000 for the main harness.

Hurst