FordTractorMan

Member

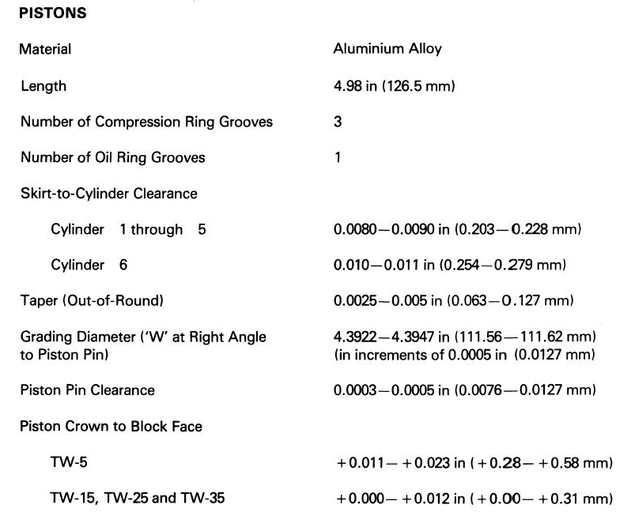

I bought a TW 35 at an auction in TN 2 yrs ago last month, and ever since I got it home, I thought it had too much blowby. Never seemed to pull the ripper quite hard enough, either. Anyway, I fixed the a.c. in it and a few other things and ran it - don't have big equipment anyway. Last fall, the blowby got worse and I heard a knocking. Finally got it torn apart Sat. and found #6 cylinder was gouged something awful. Piston looks messed up, too. Maybe the pictures will post. Engine appears to have been sleeved already, and I don't think the gouging goes through the sleeve. What do I do now? Can it be re-sleeved, or do I need to find a block?

The black streak at 12 o'clock is the damage to the sleeve.

The black streak at 12 o'clock is the damage to the sleeve.