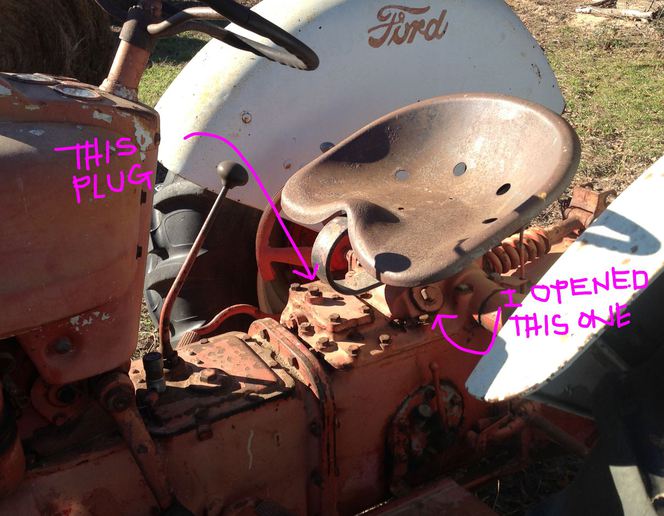

The hydraulic (lift) is stuck in the up position and will not come down. I added fluid since it was low before I got the tractor started and it went up with lever down once the tractor was running. The fluid is a milky white which indicates water in the system. On the 8N page, http://www.oldfordtractors.com/rep.htm#q20, it says this is likely a stuck valve.

1. Where to start?

2. Drain and replace?

3. A similar discussion mentions a soundguy method to get the water out?

4. A simple method to at least get the draw bar lowered?

5. General thoughts on repair cost, time, etc?

Thanks.

1. Where to start?

2. Drain and replace?

3. A similar discussion mentions a soundguy method to get the water out?

4. A simple method to at least get the draw bar lowered?

5. General thoughts on repair cost, time, etc?

Thanks.