I recently posted and received some great feedback on troubleshooting my tractor problem. I believe we"ve narrowed it down to a fuel/carb problem.

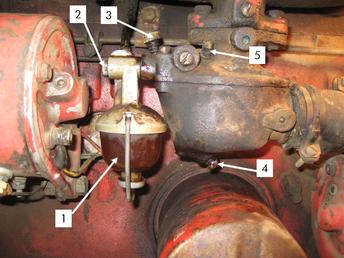

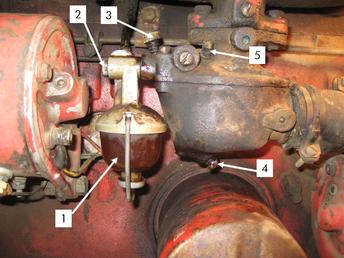

Someone suggested I may have a condensor or ballast resistor problem. I have attached a photo of my carb. Fuel seems to be flowing OK and drips consistently when I loosened screw #2. Fuel drips only slightly when I removed the plug #4. Not sure the function of #1, 3, or 5.

The tractor starts OK, then stops after 1 to 2 minutes. The throttle rod with a the spring is extended forward at first, then springs back and appears to cut off the fuel flow and the tractor dies. Then I need to wait about 5-10 minutes before the tractor will start again, before quitting after another minute or 2.

Any help or suggestions would be appreciated.

Someone suggested I may have a condensor or ballast resistor problem. I have attached a photo of my carb. Fuel seems to be flowing OK and drips consistently when I loosened screw #2. Fuel drips only slightly when I removed the plug #4. Not sure the function of #1, 3, or 5.

The tractor starts OK, then stops after 1 to 2 minutes. The throttle rod with a the spring is extended forward at first, then springs back and appears to cut off the fuel flow and the tractor dies. Then I need to wait about 5-10 minutes before the tractor will start again, before quitting after another minute or 2.

Any help or suggestions would be appreciated.