Kevin Little

Member

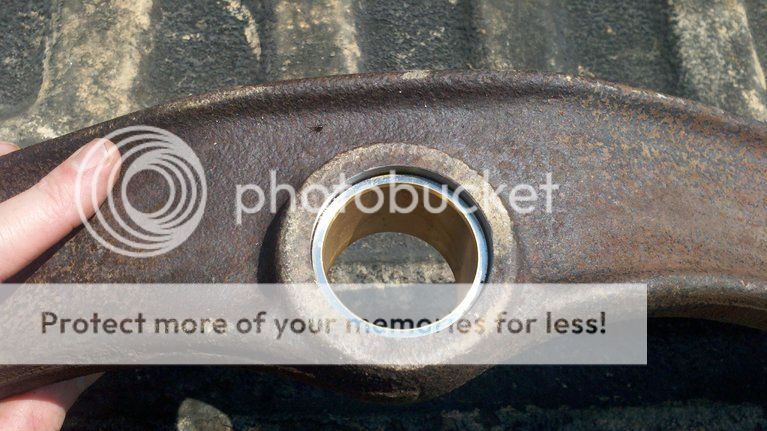

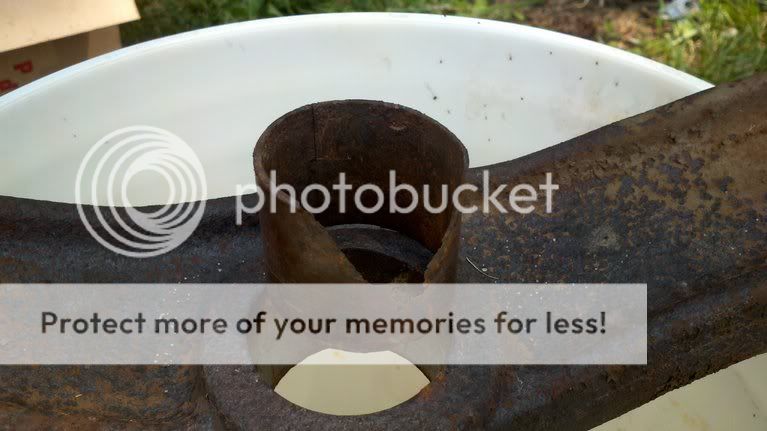

Hey all, new here, I just got my first Ferguson and the pin and bushing looks like they need to be replaced. I have the I&T shop manual and the repair itself looks pretty straight forward, but looking on the YT store site, I see two different bushings and both are different from the split bushing in the manual.

What bushing do I need? Right now, there seems to be no bushing, the axle is canted on the pin. The original engine tag is gone, but it looks like I have either a 20 with a Z129 engine swapped in or a 30 with a 20 dash and air cleaner. Any other clues to whether it's a 20 or a 30? I'm new as can be to old tractors, used to use a IH 454 on the farm growing up, so I'll be following the board here closely and probably asking a LOT of questions.

TIA.

Kevin

What bushing do I need? Right now, there seems to be no bushing, the axle is canted on the pin. The original engine tag is gone, but it looks like I have either a 20 with a Z129 engine swapped in or a 30 with a 20 dash and air cleaner. Any other clues to whether it's a 20 or a 30? I'm new as can be to old tractors, used to use a IH 454 on the farm growing up, so I'll be following the board here closely and probably asking a LOT of questions.

TIA.

Kevin