mikeroche56

Member

Hi, does anyone have the written instructions for troubleshooting and setting up T035 Hydraulics that John from UK used to send? I tried to send a request to his email, but it appears he hasn't posted in a long time, so not sure if he still is online.

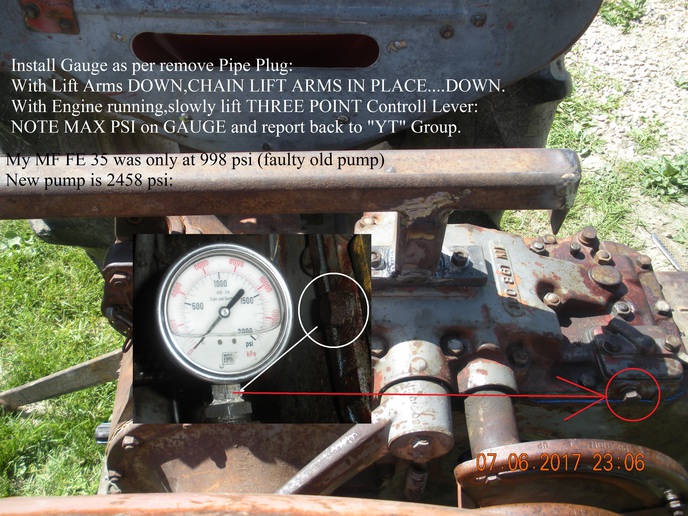

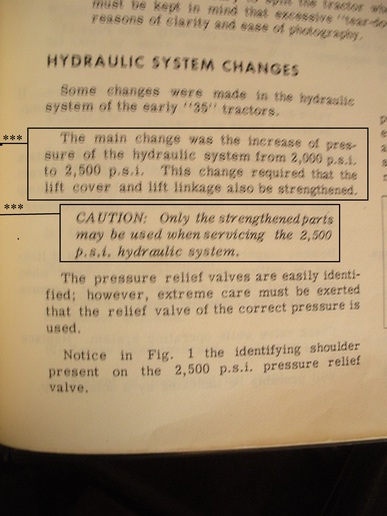

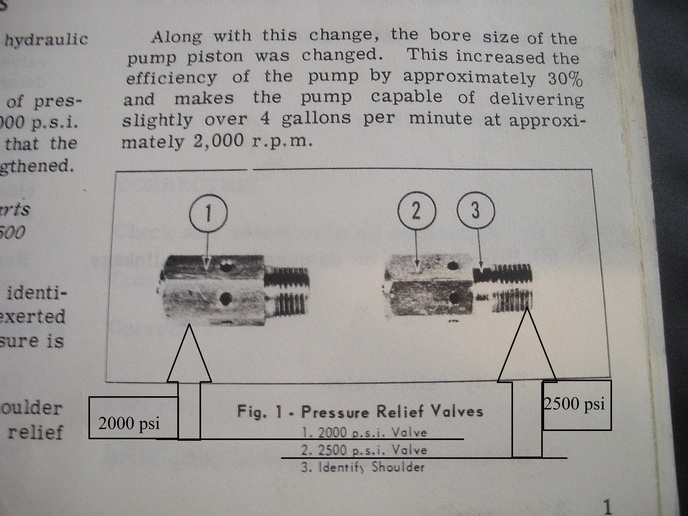

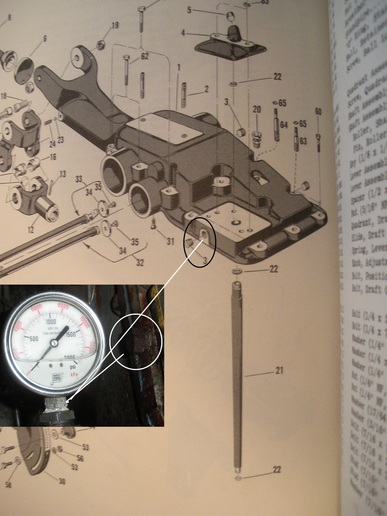

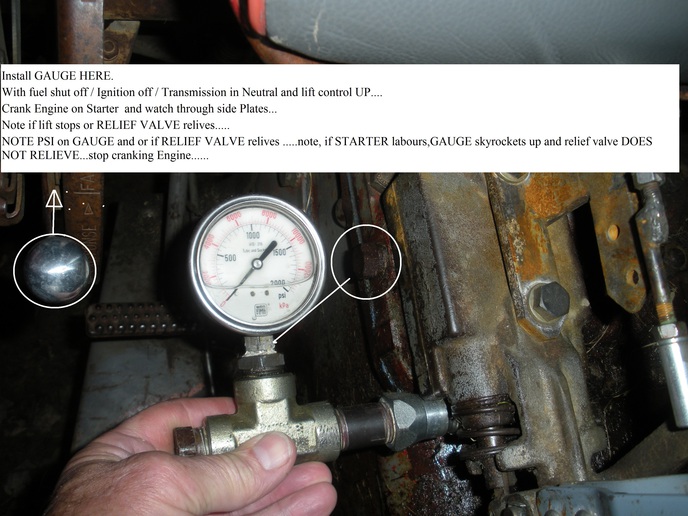

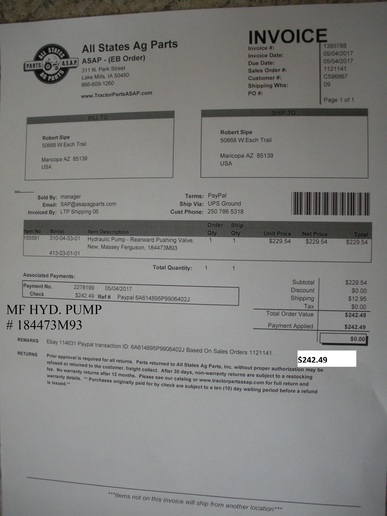

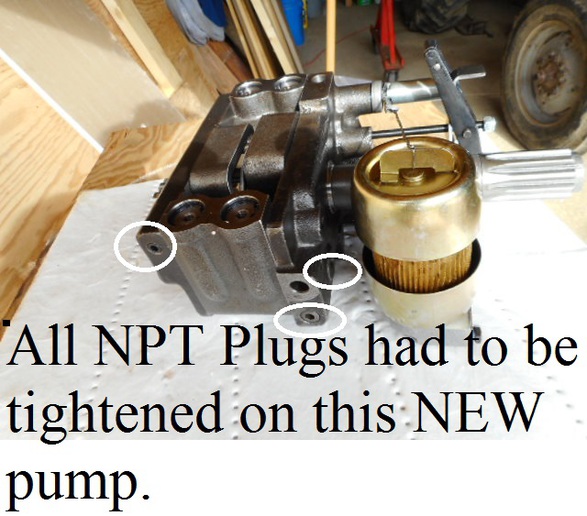

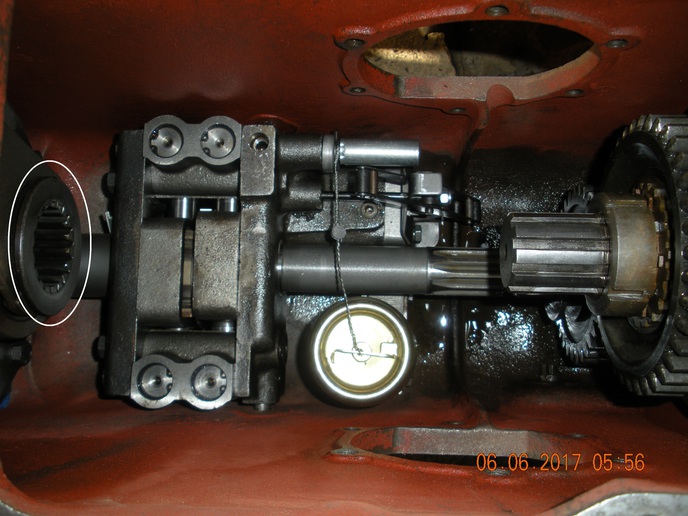

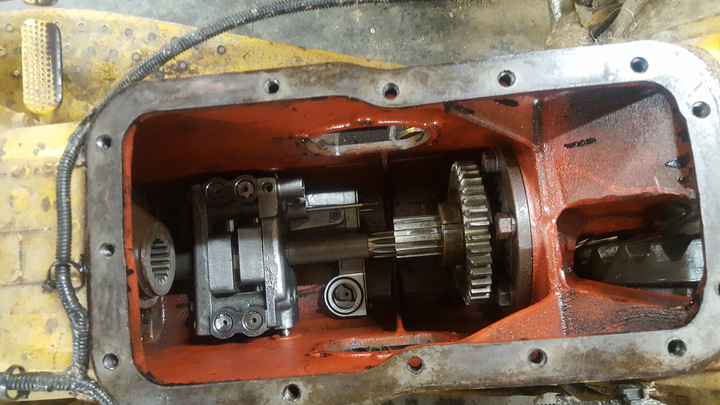

I have a 1957 TO35 and have had issues with the hydraulics dropping fairly quickly when turning the engine off. I replaced the oring seals, lift piston, rings and cylinder and relief valve, new GL1 oil to the correct level but not really any improvement. I do see some aeration of the oil after running. Thinking i may need to replace or rebuild the pump, but was hoping for some diagnostics before I spend the money/time.

The hydraulic dropping is worse as the tractor heats up and at lower RPMs it doesn't lift my brush hog very well.

Thanks for the help.

Mike

I have a 1957 TO35 and have had issues with the hydraulics dropping fairly quickly when turning the engine off. I replaced the oring seals, lift piston, rings and cylinder and relief valve, new GL1 oil to the correct level but not really any improvement. I do see some aeration of the oil after running. Thinking i may need to replace or rebuild the pump, but was hoping for some diagnostics before I spend the money/time.

The hydraulic dropping is worse as the tractor heats up and at lower RPMs it doesn't lift my brush hog very well.

Thanks for the help.

Mike