Right, as per my other posts, to overcome low hot oil pressure on a TEA20 I have now:

1. Replaced oil pump and filter (old had 6 thou wear new has 1 thou)

2. New big end bearings (old weren't too bad but I was there anyway)

3. Replaced centre main bearing (old wasn't too bad but I was there anyway)

4. Filled with 40W oil

Got pressure up by cranking and then fired up...

Pressure was right at the top end of the non graduated gauge on tickover and almost !!

Now thats fair enough to a point - with the 40W and new pump plus filter etc but I wasnt expecting so much. I have got it into the normal band with relief valve adjustment but have two questions as I'm doubting myself here !!...

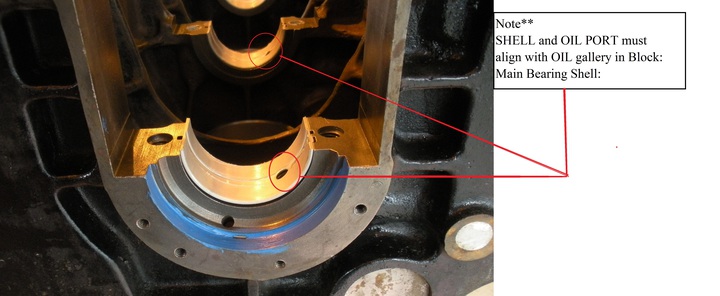

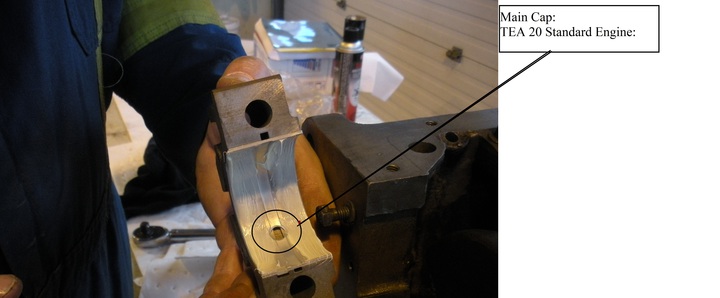

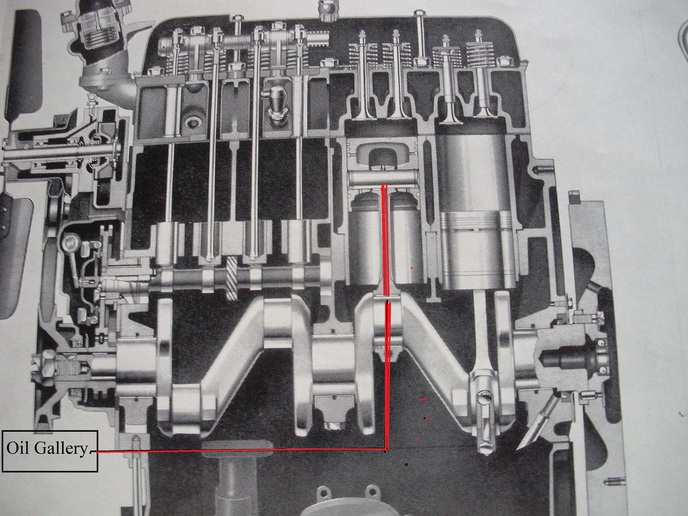

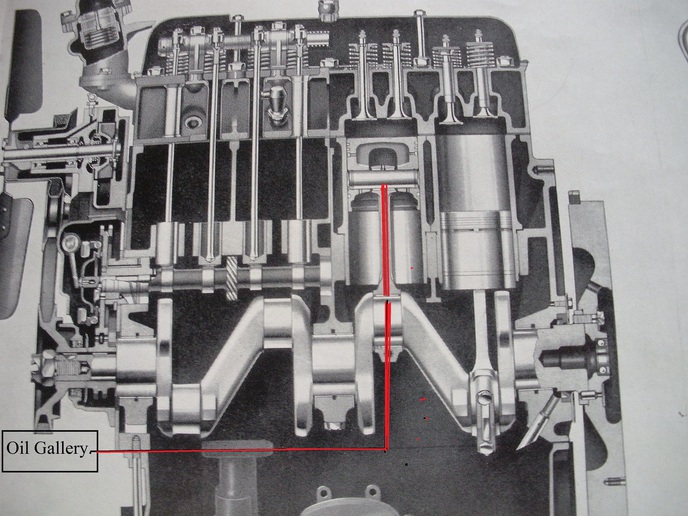

1. The main bearing shell oil holes - if misaligned on the new bearing shells from the old - would it cause high oil pressure due to no lube?? [i:e7ad32016f]My feeling is no, as the mains are grooved in the bearing cap and block to the rear of the bearing so the oil will run round to wherever the hole is,

[/i:e7ad32016f]

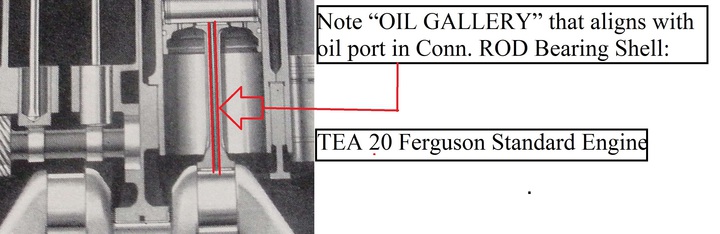

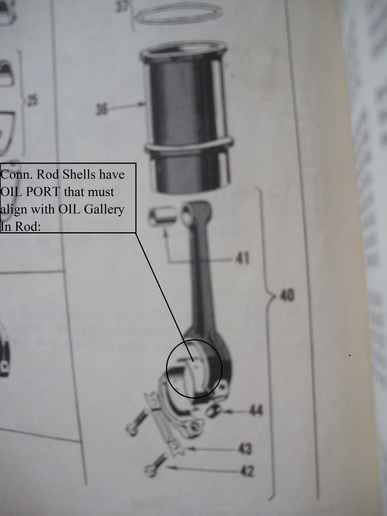

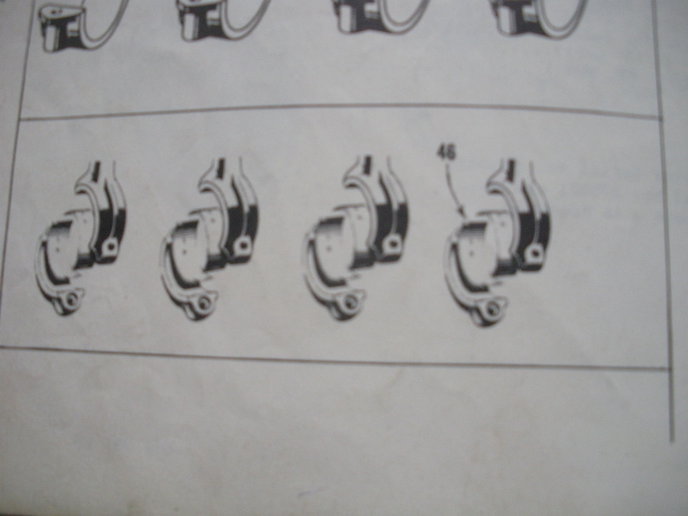

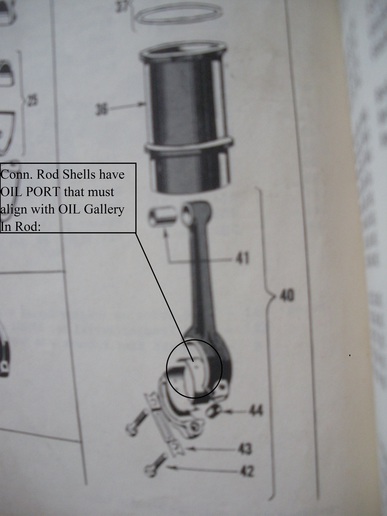

2. The big end shell oil holes - if misaligned on the new bearing shells from the old - would that cause high pressure due to no lube?? [i:e7ad32016f]My feeling is no, as the oil feed is from the crank journal so the hole in the bearing doesnt do a lot

[/i:e7ad32016f]

The bearings I bought are supposed to be correct but I never compared the old and new oil holes in situ as a double check (oops) but as above I can't honestly say any oil hole issue can be the cause to hopefully its just the pump etc that has dramatically improved the pressure...

Thanks for reading all this and any views/experiences welcomed!

1. Replaced oil pump and filter (old had 6 thou wear new has 1 thou)

2. New big end bearings (old weren't too bad but I was there anyway)

3. Replaced centre main bearing (old wasn't too bad but I was there anyway)

4. Filled with 40W oil

Got pressure up by cranking and then fired up...

Pressure was right at the top end of the non graduated gauge on tickover and almost !!

Now thats fair enough to a point - with the 40W and new pump plus filter etc but I wasnt expecting so much. I have got it into the normal band with relief valve adjustment but have two questions as I'm doubting myself here !!...

1. The main bearing shell oil holes - if misaligned on the new bearing shells from the old - would it cause high oil pressure due to no lube?? [i:e7ad32016f]My feeling is no, as the mains are grooved in the bearing cap and block to the rear of the bearing so the oil will run round to wherever the hole is,

[/i:e7ad32016f]

2. The big end shell oil holes - if misaligned on the new bearing shells from the old - would that cause high pressure due to no lube?? [i:e7ad32016f]My feeling is no, as the oil feed is from the crank journal so the hole in the bearing doesnt do a lot

[/i:e7ad32016f]

The bearings I bought are supposed to be correct but I never compared the old and new oil holes in situ as a double check (oops) but as above I can't honestly say any oil hole issue can be the cause to hopefully its just the pump etc that has dramatically improved the pressure...

Thanks for reading all this and any views/experiences welcomed!