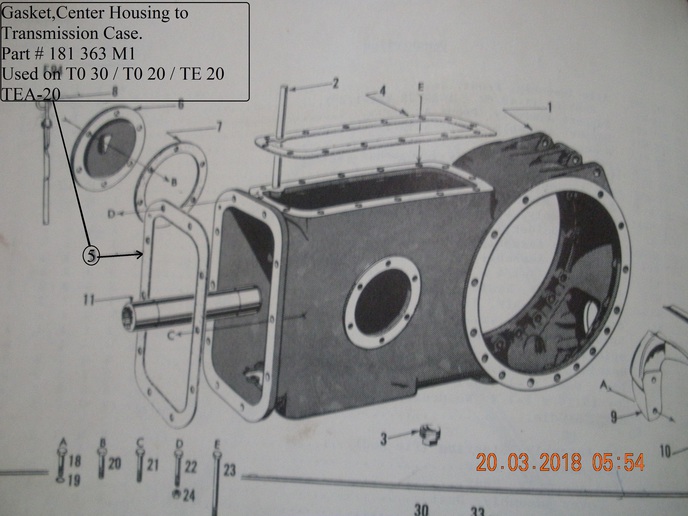

The more I get into fixing the 'little' things on this '53 TO30 to more I get into fixing 'bigger' things. I have a slow drip at the joint of the trans case & PTO case. I have not been able to locate a gasket for that joint (or the engine/trans joint) so I'm assuming there is not a gasket there but some other kind of sealant. I was watching some videos of Ferg's being put back together & in 1 video it looks like the guy used some RTV or other kind of sealant. Is that what is used to seal up the joints in the cases?

I'm thinking I'll take care of those 2 case joints now, plus that lets me get all of the rest of the chocolate milk-like oil cleaned out of the cases.

I'm thinking I'll take care of those 2 case joints now, plus that lets me get all of the rest of the chocolate milk-like oil cleaned out of the cases.