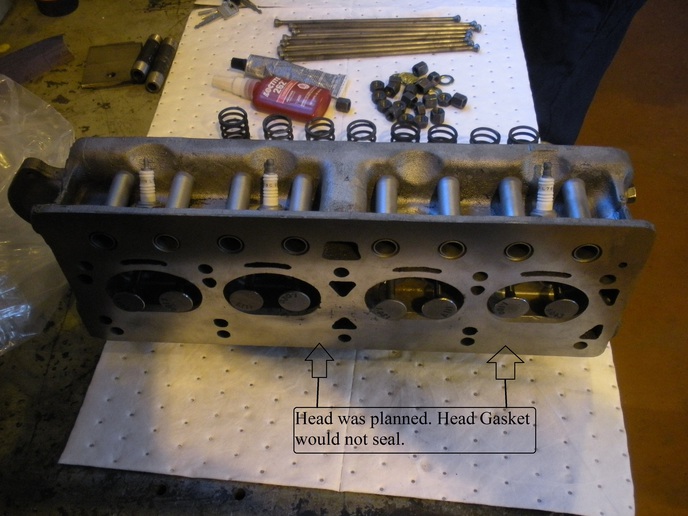

Initially I had white smoke coming from my rocker gasket. I pulled the engine apart, flushed the cooling system, pulled off the head, put on a new head gasket, manifold gaskets, new plugs, oil change and filter and a liquid rocket gasket because I did not think the cork was working. There was some carbon deposits but nothing that looked broken. It all went back together with no extra parts. It started at the first turn of the key and everything seemed good.

When I did some work with it, I noticed it was overheating. So I checked the fan direction, hoses and the thermostat. All were good.

I let it sit a while not knowing what to do. It was inside. After about 6 months, I ran it again. This time it overheated and I got white smoke out of the oil top-up and rocker. Carbon on all plugs.

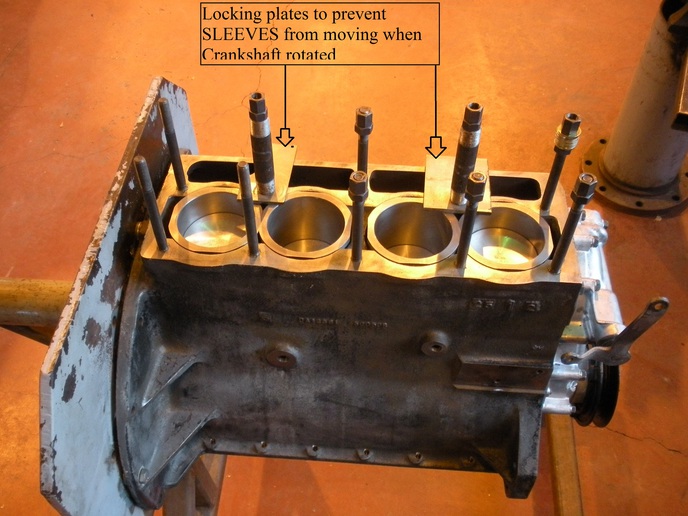

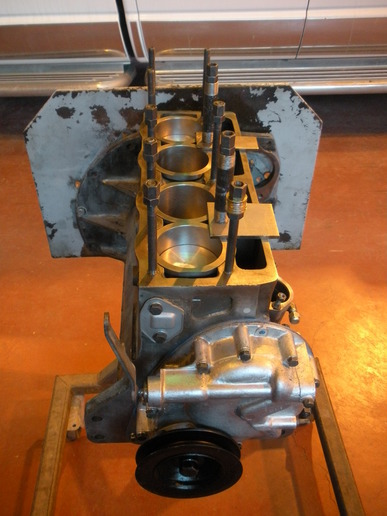

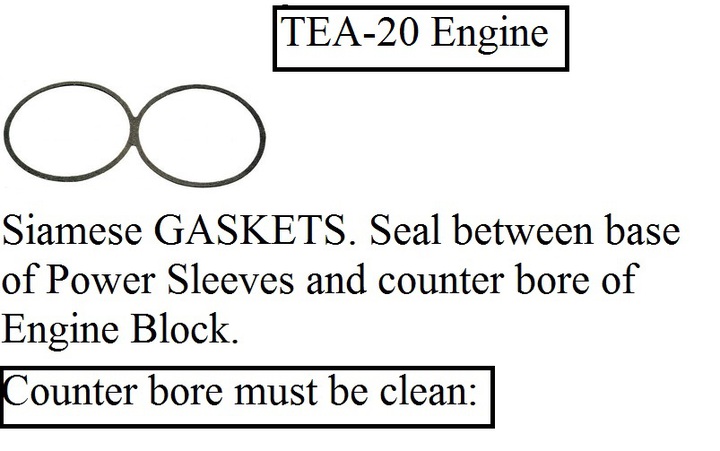

I took the engine apart again and there is rust in the rocker cover, and water was in the head and oil pan. Oil milky. There are no obvious cracks in the block. The water is siting between the cylinders and not draining out.

I did purchase the new head gasket on ebay and it was not fully copper like the old one. I was planning on purchasing a new copper head gasket and trying it again. I might add that the replaced gasket looks fine.

Could someone perhaps tell me what else I should look for?

When I did some work with it, I noticed it was overheating. So I checked the fan direction, hoses and the thermostat. All were good.

I let it sit a while not knowing what to do. It was inside. After about 6 months, I ran it again. This time it overheated and I got white smoke out of the oil top-up and rocker. Carbon on all plugs.

I took the engine apart again and there is rust in the rocker cover, and water was in the head and oil pan. Oil milky. There are no obvious cracks in the block. The water is siting between the cylinders and not draining out.

I did purchase the new head gasket on ebay and it was not fully copper like the old one. I was planning on purchasing a new copper head gasket and trying it again. I might add that the replaced gasket looks fine.

Could someone perhaps tell me what else I should look for?