Bill in Brunswick

Member

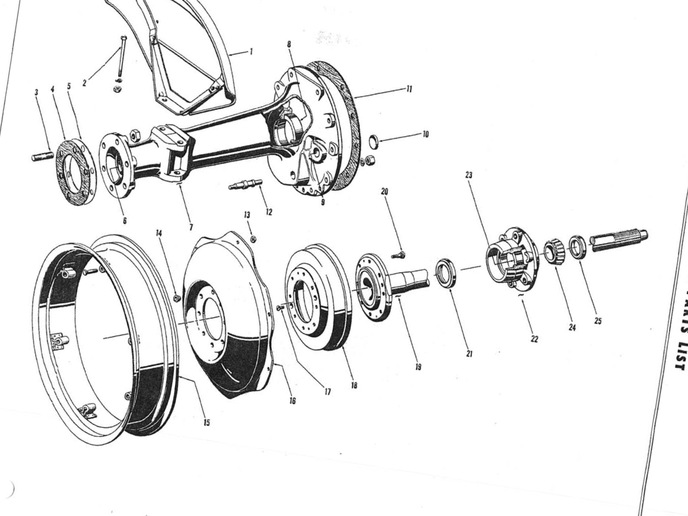

My TO30 has leaky rear axle oil seals that need to be replaced. I've read the Ferguson shop manual. I have the Ferguson Parts manual on order. I still feel like I'm going to run into things I'm not expecting (which I know is part of every job, but I'd like to minimize the surprises if possible  )

)

Are there any procedures out there that have more detail than the shop manual?

I have some of John(UK)'s manuals on other TO30 stuff, but not on replacing the oil seals. Anyone have a manual John(UK) wrote on replacing oil seals?

Thanks for the great forum and for all the help over the years !!!

Are there any procedures out there that have more detail than the shop manual?

I have some of John(UK)'s manuals on other TO30 stuff, but not on replacing the oil seals. Anyone have a manual John(UK) wrote on replacing oil seals?

Thanks for the great forum and for all the help over the years !!!