MarkDennis

New User

Couple of you-tube clips below of my TEA20 that I am not restoring, just looking to get it to some sort of running order.

It will sit and idle happily all day but when I bring the revs up to half and then full throttle it surges quite badly. I can push & hold the governor lever assembly with my hand it will rev freely throughout the range. I have turned in the bumper screw as far as I dare without any noticeable improvement.

The timing has been checked & the points set. The 24t is also set as per the manual

Am I going to have to remove the timing cover and have a look around ?

Any suggestions greatly appreciated

https://www.youtube.com/watch?v=wsjQR4BnRT8

https://www.youtube.com/watch?v=2yXlhHCG1fI&feature=em-upload_owner

It will sit and idle happily all day but when I bring the revs up to half and then full throttle it surges quite badly. I can push & hold the governor lever assembly with my hand it will rev freely throughout the range. I have turned in the bumper screw as far as I dare without any noticeable improvement.

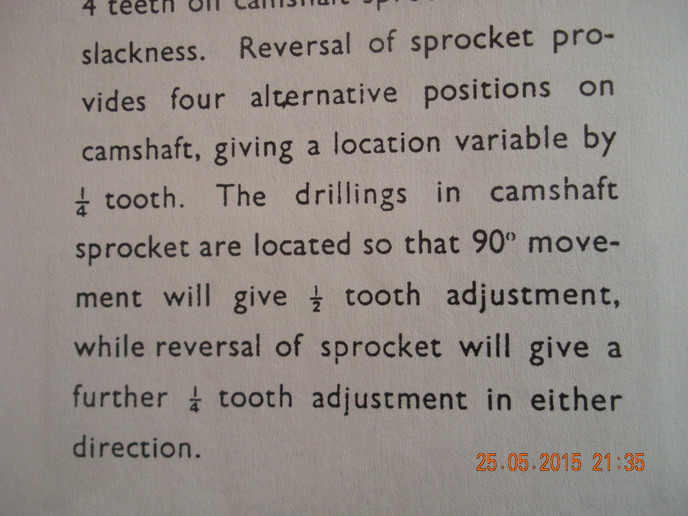

The timing has been checked & the points set. The 24t is also set as per the manual

Am I going to have to remove the timing cover and have a look around ?

Any suggestions greatly appreciated

https://www.youtube.com/watch?v=wsjQR4BnRT8

https://www.youtube.com/watch?v=2yXlhHCG1fI&feature=em-upload_owner