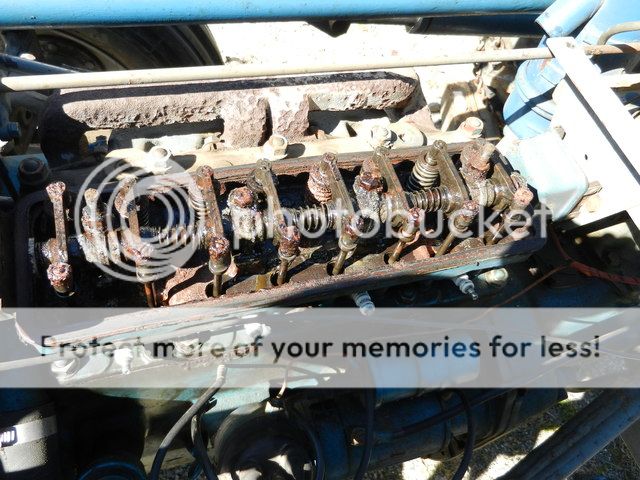

TO 30 parked since 2000:

After removing old oil filter cartage, observing it was very unused clean except for the lower portion that was sitting in a pool of sludge caused me to think oil was not passing through filter.

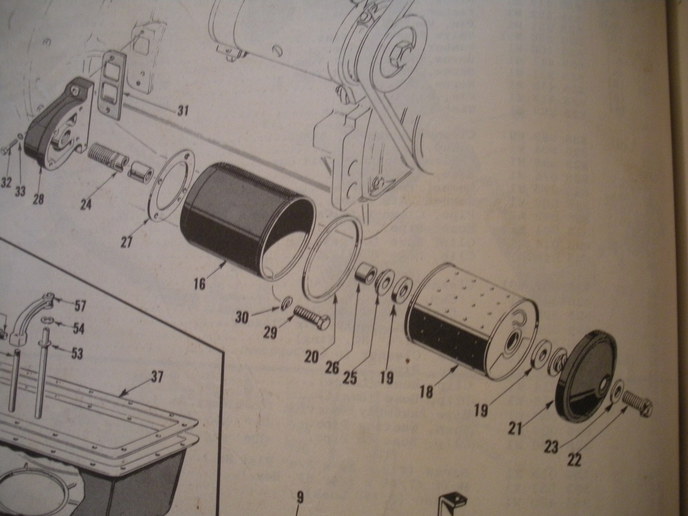

After factory parts book, it appears that a spacer is missing listed in blowup as number 56 181728 M1 that is first on center shaft followed by a washer no. 55 1008251 M1which I may have if it is a black neoprene like material, and a gasket No 53 1006594 M1 that seals the bolt that holds the cover on.

Where could I get these parts, 56 and 53, new or used?

Also because of the side arms that are part of front bucket preventing one to position one's head for a look see into empty canister leaves me puzzled as to how the oil enters filter. There seams to be no holes in center tube which cover bolt screws into, and filter I got from FM dealer has no perforations at its ends. Looks as if oil should flow into center of filter, then forced under pressure to out side of filter, collected in canister until is runs back to sump by gravity.

After removing old oil filter cartage, observing it was very unused clean except for the lower portion that was sitting in a pool of sludge caused me to think oil was not passing through filter.

After factory parts book, it appears that a spacer is missing listed in blowup as number 56 181728 M1 that is first on center shaft followed by a washer no. 55 1008251 M1which I may have if it is a black neoprene like material, and a gasket No 53 1006594 M1 that seals the bolt that holds the cover on.

Where could I get these parts, 56 and 53, new or used?

Also because of the side arms that are part of front bucket preventing one to position one's head for a look see into empty canister leaves me puzzled as to how the oil enters filter. There seams to be no holes in center tube which cover bolt screws into, and filter I got from FM dealer has no perforations at its ends. Looks as if oil should flow into center of filter, then forced under pressure to out side of filter, collected in canister until is runs back to sump by gravity.