(quoted from post at 22:13:00 02/14/14) I think the 58 is a late style, the pump should be

repairable.

It would be easier to buy a rebuilt pump though. I

rebuilt mine, but had trouble with some of the

clearances, would not turn when everything was

tightened up. Having access to a surface grinder I

was able to make adjustments, otherwise I would

have been in a fix!

You may still want to check for leakage from the

cylinder seals and stand pipe before pulling the

pump.

With both inspection covers off, raise the arms,

(preferably with some weight on them), CAREFULLY

look up inside the case with a flashlight,

remember, moving parts inside!

Look for dripping or spraying hydraulic oil coming

down from under the seat area. This is where the

hydraulic cylinder is. There will be a slight drip

of oil, but it should not be flowing.

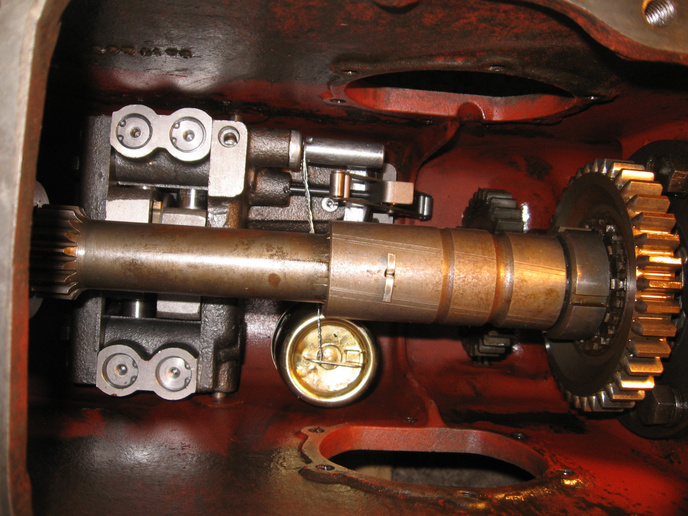

The pump comes out through the top, no need to

split the case. Getting the top cover off and on

is the hardest part, it's heavy and bulky, 2

people required.

While you're in there, it would be easy to replace

the cylinder seal rings and hone the cylinder

bore. There will be some scratches in the bore,

but unless it's severe, it will be OK. There is

also a rubber boot around the top link, where the

top 3 point attaches. It needs to be in good

condition to keep water out of the transmission.