I did a 12 volt conversion on my Farmall H from the link below a couple years ago but it starts poorly and seems to start best when I let off the starter button. So I ran a wire from from the lug on the starter to the output side of resistor to give the coil full 12 volts at cranking. But adding the wire back feeds power to the starter when I pull out the ignition switch.

I think I need A diode in that wire to the starter, but I dodn't know anything about diodes.

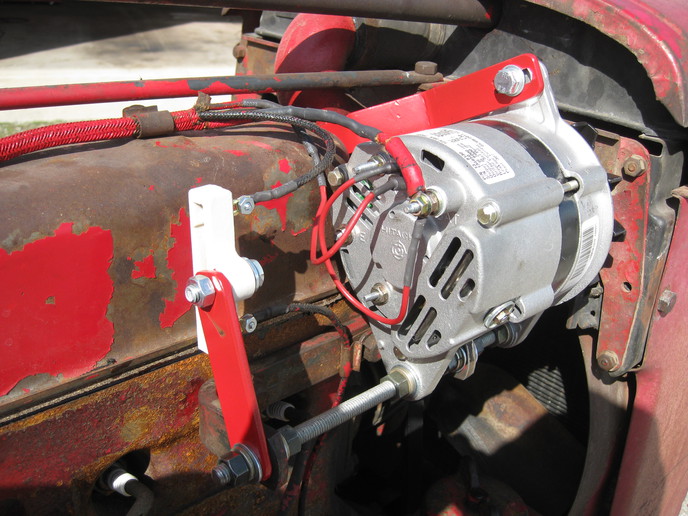

I did add the 1N4001 on the alternator but dodn't if that would be heavy enough in this situation.

I know I could put a toggle switch in the wire but did not want to go that route.

Thanks, Mark

12 volt conversian

I think I need A diode in that wire to the starter, but I dodn't know anything about diodes.

I did add the 1N4001 on the alternator but dodn't if that would be heavy enough in this situation.

I know I could put a toggle switch in the wire but did not want to go that route.

Thanks, Mark

12 volt conversian