Hello all,

I am planning for my spring project to set-up my M for two way cylinders. is this the right valve?

http://www.northerntool.com/shop/tools/product_200416981_200416981?isSearch=314366

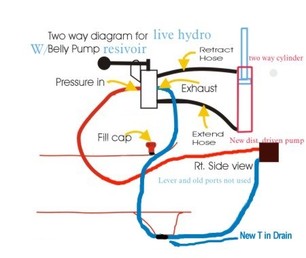

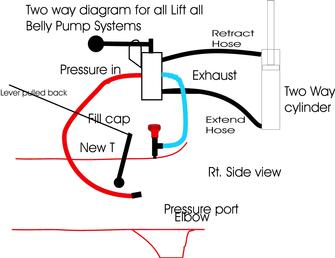

And what dia. hydro hoses are recommended. I know I'll need four hoses. two for the valve to lift-all and two to the back of tractor. I plan to tee it in the belly pump drain. Beyond that have I missed anything major? Thanks for he help in advance.

I am planning for my spring project to set-up my M for two way cylinders. is this the right valve?

http://www.northerntool.com/shop/tools/product_200416981_200416981?isSearch=314366

And what dia. hydro hoses are recommended. I know I'll need four hoses. two for the valve to lift-all and two to the back of tractor. I plan to tee it in the belly pump drain. Beyond that have I missed anything major? Thanks for he help in advance.