JTM Nashville

New User

My 574 diesel lifts the three point "very" slowly with just a little weight on it (about 200 lbs.). It drops fine. With no weight it goes up and down fine. Here are some notes:

1. New hydraulic pump installed.

2. New main pressure relief valve.

3. New filter and very clean fluid.

4. Measure 1800+ psi at remotes.

5. Power steering works great.

6. PTO works great (runs a 7' bushog fine).

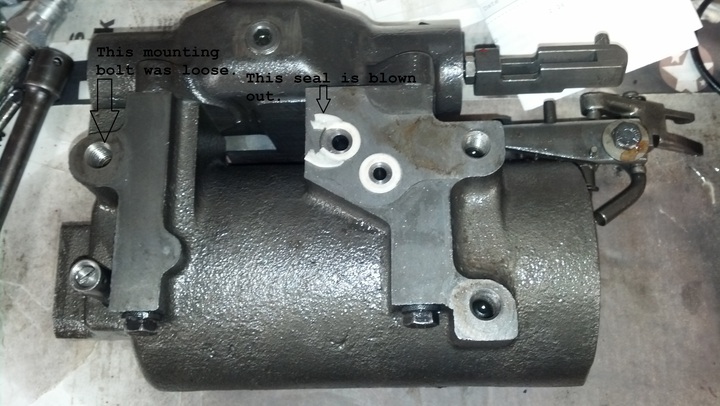

7. Rebuilt the MCV with new O rings and gasket.

8. Replaced O rings in unloading/flow control assembly.

9. The unloading/flow control valve moves freely in it's bore. No visable scoring.

10. Disassembled and cleaned the variable flow control valve.

11. Dead heading the remote in either direction causes the relief valve to squeal.

12. Replaced lift cylinder O ring and backup seal.

13. Disasembled and cleaned action control valve.

The only item not yet removed and checked is the seat for the unloading valve piston. The piston O ring has been replaced however.

I have been using the I&T Shop Service manual to troubleshoot and rebuild the hydraulics. Any suggestions here would be appreciated.