Zachary Hoyt

Well-known Member

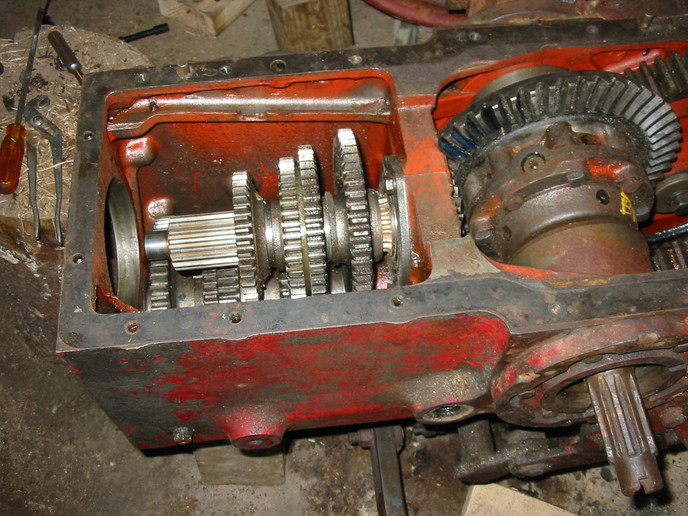

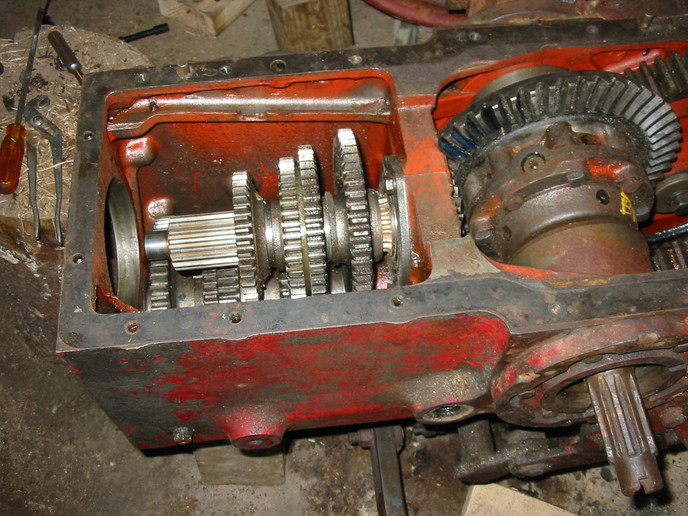

I got the upper transmission shaft back in today and was going

to check the gear mesh but ran into two problems. The prussian

blue did not seem to like the temperature, around 16 F, even

though I had kept it inside and then in my pocket. It seemed

that as soon as I touched it to the gear teeth it became a very

thick paste that was hard to spread into an even film. The

second problem was that the upper shaft has about 1/8" of play

at the front end which it seems to me is likely to throw off the

reading. It looks like I will have to unsplit the TA from the

transmission before checking the mesh. I got started taking the

TA apart to replace the output shaft/constant mesh gear but I

have a way to go yet. I had it all apart back in the summer so at

least there should not be any stuck bolts or any excessive level

of confusion. I will get back at it tomorrow, which is supposed

to be warmer.

Zach

to check the gear mesh but ran into two problems. The prussian

blue did not seem to like the temperature, around 16 F, even

though I had kept it inside and then in my pocket. It seemed

that as soon as I touched it to the gear teeth it became a very

thick paste that was hard to spread into an even film. The

second problem was that the upper shaft has about 1/8" of play

at the front end which it seems to me is likely to throw off the

reading. It looks like I will have to unsplit the TA from the

transmission before checking the mesh. I got started taking the

TA apart to replace the output shaft/constant mesh gear but I

have a way to go yet. I had it all apart back in the summer so at

least there should not be any stuck bolts or any excessive level

of confusion. I will get back at it tomorrow, which is supposed

to be warmer.

Zach