Zachary Hoyt

Well-known Member

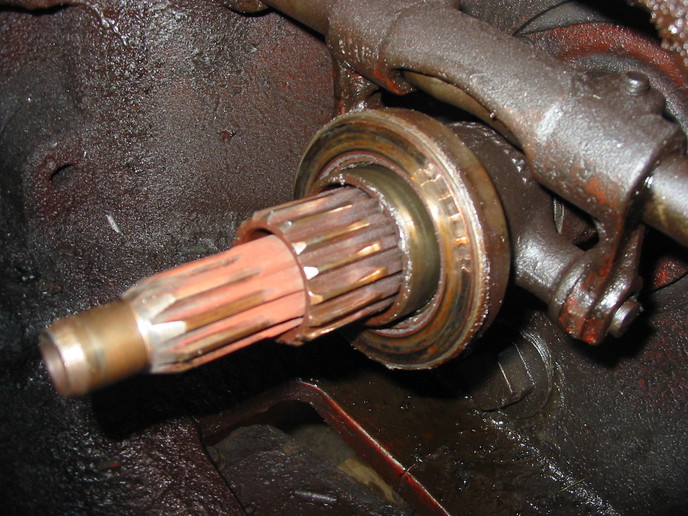

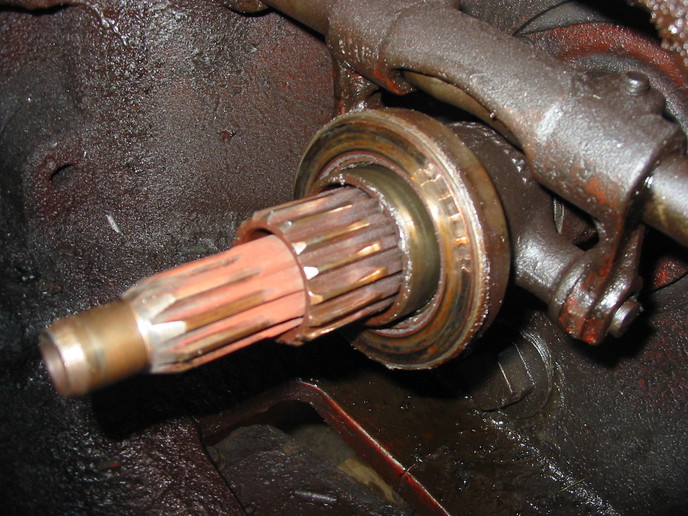

I split it last night. I hope my splitting stand doesn't give anyone the heebie-jeebies, I think it is quite sufficient to support the weight and the frame rails are lag bolted to the skid so it should stay together. The splines in the pressure plate are almost completely gone, the ones on the shaft are damaged and I assume I should replace that too. The clutch disk is not down to the rivets yet but maybe I should just replace it while I'm in there. The TO bearing is rough, but the pilot bearing seems fine. I am planning to move the front out of the way and remove the center housing so I can pull out the TA and see if it needs to be replaced with a rebuilt unit. It looks like it was run in almost low position for a while based on where the TA lever latch is positioned and the fact that the broken off lever was rusted in place solidly. Is there anything I need to do to remove the center housing other than disconnecting the clutch and TA linkages, supporting the weight and removing the bolts? I am particularly wondering about the IPTO driveshaft and how that is affected. Any advice will be much appreciated.

Zach

Zach