charles todd

Well-known Member

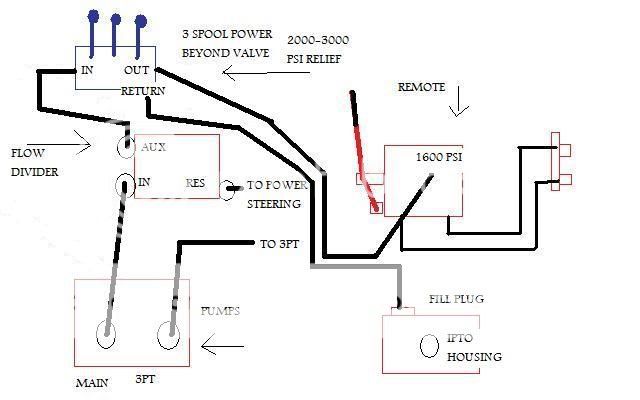

I replaced my 12GPM pump with a fresh 17GPM pump on my Farmall 504 recently. I bought both pump cover gaskets (.019 and .024) and used the original gear. The gears looked good and I think I used the .019 gasket. I put in new filters and all new orings. I believe the original style filters are only good for the 12GPM pump. I called (Precision Products?) who make a spacer that allows use of a larger, modern filter that can handle the flow, but is backordered.

I have said this to get to the problem. When running there is a high pitched whine that sounds like it is comming from the flow divider.

I had my father listen to it and he thinks it is from the increased turbulent flow though the rubber hydraulic hose (not stock) causing the noise. I think it may be the gear mesh is too tight transmitting the sound up the hose. Or it could be the flow divider some how resonating? Or the pump is starving with the smaller filters...

Is this normal or acceptable with a new pump? The hydraulics are FAST and the steering works much better. It just has a whine now.

I know Hugh, Allan, Rusty and the like can probably help here.

Thanks and I apoligize in advance for the long post,

Charles

I have said this to get to the problem. When running there is a high pitched whine that sounds like it is comming from the flow divider.

I had my father listen to it and he thinks it is from the increased turbulent flow though the rubber hydraulic hose (not stock) causing the noise. I think it may be the gear mesh is too tight transmitting the sound up the hose. Or it could be the flow divider some how resonating? Or the pump is starving with the smaller filters...

Is this normal or acceptable with a new pump? The hydraulics are FAST and the steering works much better. It just has a whine now.

I know Hugh, Allan, Rusty and the like can probably help here.

Thanks and I apoligize in advance for the long post,

Charles