charles todd

Well-known Member

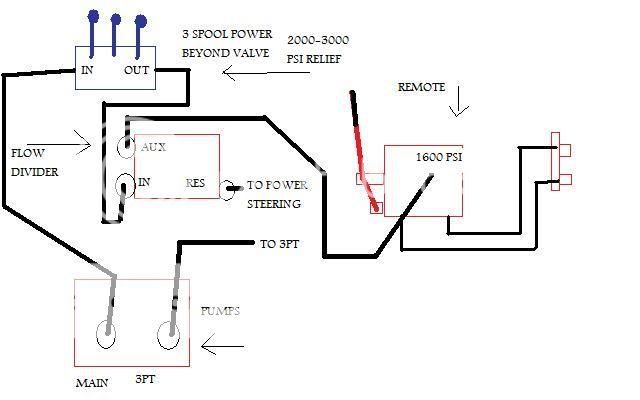

Tractor in question is a Farmall 504 Diesel. I am interested in putting a 3 spool valve bank on my Kokyer 220 loader. I believe open-center, power beyond, built-in-regulated valve bank will work.

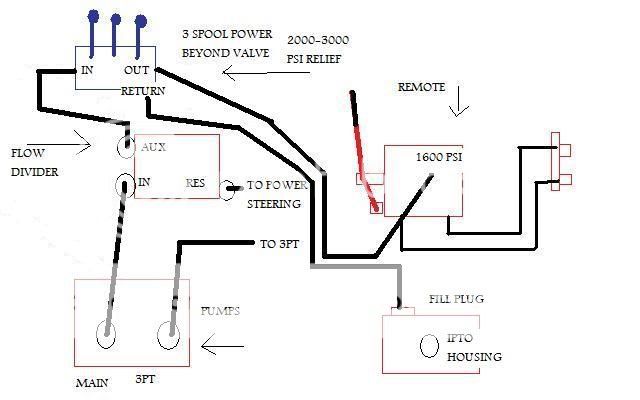

[b:744370b11d]This is what I've got in stock form...[/b:744370b11d]

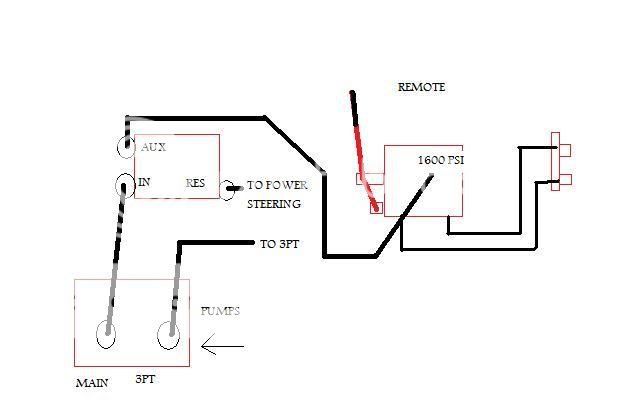

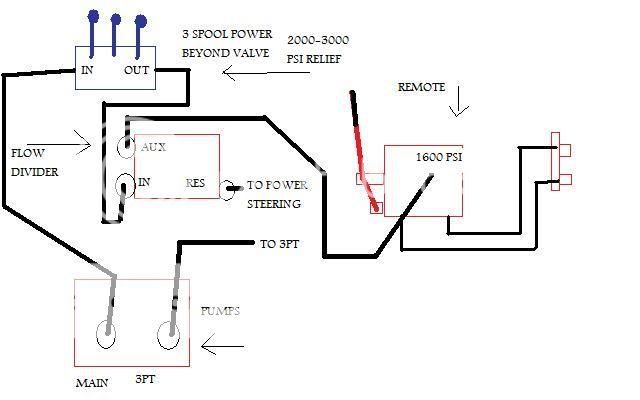

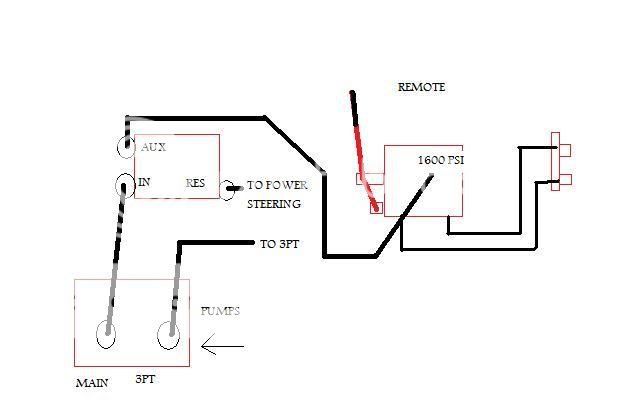

[b:744370b11d]This is what I think I need to do...[/b:744370b11d]

I apoligize for the crude diagrams, I do not have AutoCad installed on this computer. Can I go from the pump to the Inlet of the new valve and then out to the PS flow divider? It seems that this is all that is needed... or am I missing a return line? I can put 2000-2500 psi on the 3 spool and the stock 1600 psi will work for the remotes.

Whatcha think guys? Is it this simple, just add a power beyond valve in series between the pump and flow divider? When the loader is removed, just plug the lines in to themselves for OEM plumbing?

Thanks, I have been putting much thought into this...

Charles

[b:744370b11d]This is what I've got in stock form...[/b:744370b11d]

[b:744370b11d]This is what I think I need to do...[/b:744370b11d]

I apoligize for the crude diagrams, I do not have AutoCad installed on this computer. Can I go from the pump to the Inlet of the new valve and then out to the PS flow divider? It seems that this is all that is needed... or am I missing a return line? I can put 2000-2500 psi on the 3 spool and the stock 1600 psi will work for the remotes.

Whatcha think guys? Is it this simple, just add a power beyond valve in series between the pump and flow divider? When the loader is removed, just plug the lines in to themselves for OEM plumbing?

Thanks, I have been putting much thought into this...

Charles