Thanks for all the advice on safety, the remaining two bolts, and MOST of all leaving those bolts in by the frame rail. After you guys pointed that out I saw how that would have gone bad quickly once apart.

Prior to tear down I had checked the clutch and the pedal freeplay was adjusted dead on per the IH manual but on some shifts from a dead stop she would grind so I suspected maybe some other components were worn.

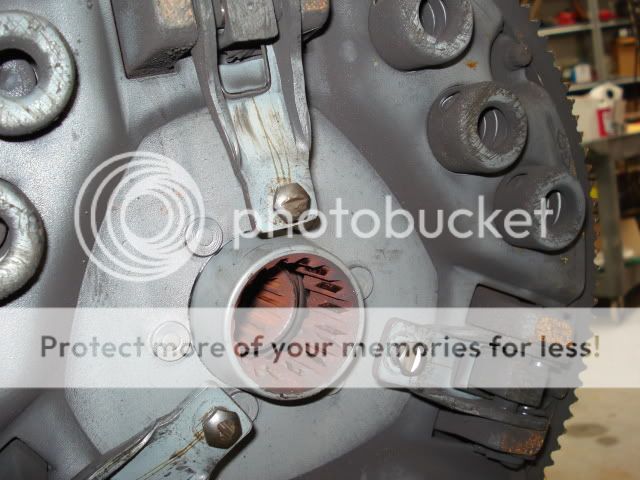

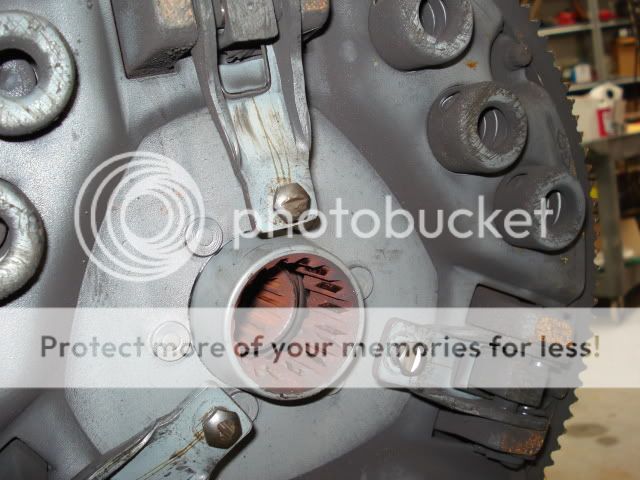

The friction pads measure between .370 and .371. I don't know what spec to match this up to in the manual. The pressure plate and flywheel look good. Do I just replace the disc? Looks like someone's been in here prior. Don't know why they didn't replace the rear main then. The rubber on the seal was ancient.

I was surprised to see wear on the bolt heads that ride on the throw out bearing. Are these available separately and do I just locktite them in or is there a different way to address this. Could I weld them up and grind them back down or is that crazy talk? Is this why my pedal measured ok but I would get gear grind?

Found two pieces of steel about 1/8" thick and dimension of a finger nail in the clutch housing. Maybe they are the shipping spacers from the last clutch installed?

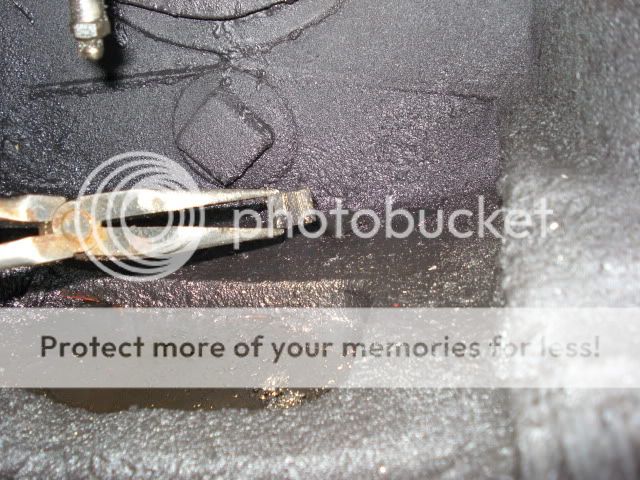

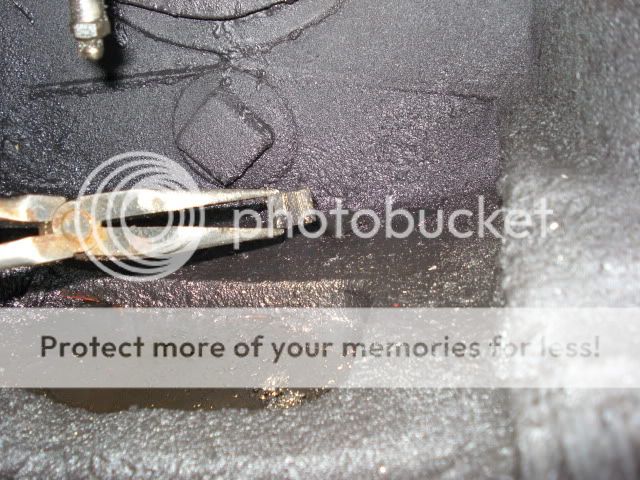

Originally I thought I might get by with just rings and bearings. Nope. Check out the stacked compression ring on #1! (cracked skirts on 3 out of 6 pistons).

So I'm pulling the sleeves. Even using the 18" crescent it took a lot more effort than I expected to turn the nut on the homemade puller.

The first one is out. Grinding the plate at the bottom to be just right was kind of fun.

Blessed with 2" of rain this week; pastures are GREEN! Got to make sure I have this thing back up and running before 1st cut.

Prior to tear down I had checked the clutch and the pedal freeplay was adjusted dead on per the IH manual but on some shifts from a dead stop she would grind so I suspected maybe some other components were worn.

The friction pads measure between .370 and .371. I don't know what spec to match this up to in the manual. The pressure plate and flywheel look good. Do I just replace the disc? Looks like someone's been in here prior. Don't know why they didn't replace the rear main then. The rubber on the seal was ancient.

I was surprised to see wear on the bolt heads that ride on the throw out bearing. Are these available separately and do I just locktite them in or is there a different way to address this. Could I weld them up and grind them back down or is that crazy talk? Is this why my pedal measured ok but I would get gear grind?

Found two pieces of steel about 1/8" thick and dimension of a finger nail in the clutch housing. Maybe they are the shipping spacers from the last clutch installed?

Originally I thought I might get by with just rings and bearings. Nope. Check out the stacked compression ring on #1! (cracked skirts on 3 out of 6 pistons).

So I'm pulling the sleeves. Even using the 18" crescent it took a lot more effort than I expected to turn the nut on the homemade puller.

The first one is out. Grinding the plate at the bottom to be just right was kind of fun.

Blessed with 2" of rain this week; pastures are GREEN! Got to make sure I have this thing back up and running before 1st cut.