02WS6SSZ71

New User

I'll try to keep this as short as possible, but in short I'm dealing with a PIG RICH condition after a carb rebuild.

Recently purchased '57 350, ran pretty well when I dragged it home. The stand pipe off the manifold had been goober brazed

at some point and broke loose when I pulled the muffler off, and carb was a little leaky, so I pulled it all, put on a new

manifold and gaskets, set valves, and did a complete rebuild on the carb, including throttle shaft bushings and a new float.

Soaked in Berrymans for a couple days, sprayed all passages with carb cleaner, and blew everything out with air for cleanup.

Put it back on the tractor and it was clearly rich with black smoke at idle and throttled up. New plugs were installed

before startup and they were black after a short run, def fuel, not oil. Idle air screw changed nothing at idle, all the

way in and all the way out, no change in RPM or richness. Main high idle screw turned all the way in to half turn from

seated did nothing to help.

I pulled it all back down and assumed I still had junk in carb passages somewhere. Into the ultrasonic cleaner for a good

12 hrs. Got quite a bit of black crap out of it and figured I had it licked. I did compare the main jet this time around

and noticed that the old jet had 3 equal sized sets of holes, whereas the new jet had one hole (closet to the threads)

larger than the other two. I called the provider of the carb kit and he confirmed that the proper jet for the 350 should

have one pair of holes larger than the other two, so I left the new jet in and assumed the trash was likely causing bypass

of the idle circuit and creating my rich condition. Put the carb back on, same result.

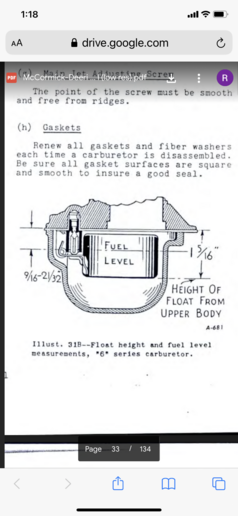

Float was set to spec (1-5/16) with machinist measure in 64ths, throttle body upside down, no gasket, checked both sides on

the float to make sure they were equal. With the tractor off, gas flow open, there was no gas running into the bottom of

the carb bowl so I know the needle/seat was doing its job. However, on the 2nd rebuild I did find that if I shut the

tractor off without shutting off the gas first I would see a little gas spill down and run out the weep hole in the bottom

of the carb. I found a spec for checking the float externally so I set up a clear tube off the carb drain. Spec showed gas

should come up the clear tube to within 9/16-21/32 of the carb parting line...mine was 3/8 from the parting line....damn

near a 1/4 too high! Left sit for 15 min and it never climbed, confirming needle and seat working.

How could I set the float dead on and have the outside level appear to be so far off? How far should I tweak the float to

try to correct this? Surely not 1/4... Should I be looking somewhere else? Is the main jet a concern to anyone? Should

I put the old jet in or just monkey with the float first? Any thoughts/suggestions greatly appreciated.

Recently purchased '57 350, ran pretty well when I dragged it home. The stand pipe off the manifold had been goober brazed

at some point and broke loose when I pulled the muffler off, and carb was a little leaky, so I pulled it all, put on a new

manifold and gaskets, set valves, and did a complete rebuild on the carb, including throttle shaft bushings and a new float.

Soaked in Berrymans for a couple days, sprayed all passages with carb cleaner, and blew everything out with air for cleanup.

Put it back on the tractor and it was clearly rich with black smoke at idle and throttled up. New plugs were installed

before startup and they were black after a short run, def fuel, not oil. Idle air screw changed nothing at idle, all the

way in and all the way out, no change in RPM or richness. Main high idle screw turned all the way in to half turn from

seated did nothing to help.

I pulled it all back down and assumed I still had junk in carb passages somewhere. Into the ultrasonic cleaner for a good

12 hrs. Got quite a bit of black crap out of it and figured I had it licked. I did compare the main jet this time around

and noticed that the old jet had 3 equal sized sets of holes, whereas the new jet had one hole (closet to the threads)

larger than the other two. I called the provider of the carb kit and he confirmed that the proper jet for the 350 should

have one pair of holes larger than the other two, so I left the new jet in and assumed the trash was likely causing bypass

of the idle circuit and creating my rich condition. Put the carb back on, same result.

Float was set to spec (1-5/16) with machinist measure in 64ths, throttle body upside down, no gasket, checked both sides on

the float to make sure they were equal. With the tractor off, gas flow open, there was no gas running into the bottom of

the carb bowl so I know the needle/seat was doing its job. However, on the 2nd rebuild I did find that if I shut the

tractor off without shutting off the gas first I would see a little gas spill down and run out the weep hole in the bottom

of the carb. I found a spec for checking the float externally so I set up a clear tube off the carb drain. Spec showed gas

should come up the clear tube to within 9/16-21/32 of the carb parting line...mine was 3/8 from the parting line....damn

near a 1/4 too high! Left sit for 15 min and it never climbed, confirming needle and seat working.

How could I set the float dead on and have the outside level appear to be so far off? How far should I tweak the float to

try to correct this? Surely not 1/4... Should I be looking somewhere else? Is the main jet a concern to anyone? Should

I put the old jet in or just monkey with the float first? Any thoughts/suggestions greatly appreciated.