dharmab434

Member

I have an early '60s vintage B-434 that has served me well for the past 30 years but now needs some TLC. I am currently replacing the wheels due to them rusting out and thought I would take the time to investigate an axle leak, change the gear box oil and try and figure out why the clutch isn't disengaging the gear box from the engine.

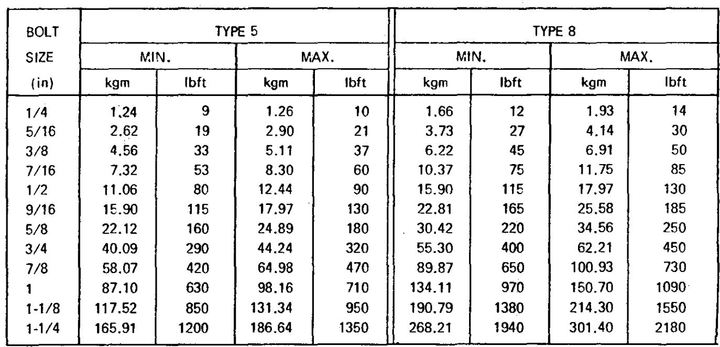

1. The leak appears to be on the left side where the rear axle carrier meets the differential housing. I suspect it's a gasket that has failed and it's a rather steady drip but I found a few loose bolts. Anybody know the torque spec?

2.The oil I drained out of the three drains looks like cafe au lait and smells pretty foul. What is the correct oil to use to fill this? The manual I have is for the US made 424 and 444 and specs IH Hy-Tran fluid. What is the correct fluid for the British made B-434?

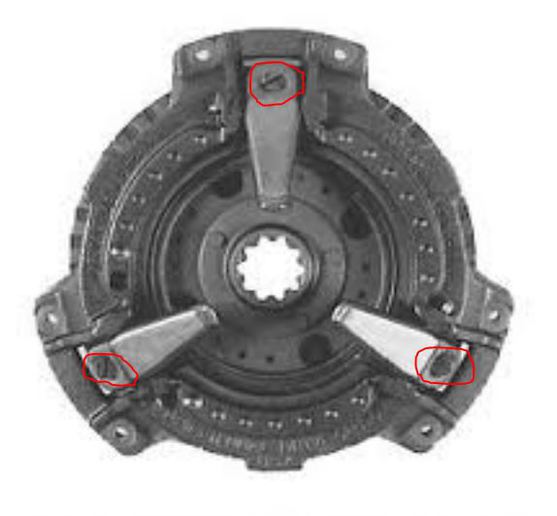

3. I have checked the clutch pedal height and travel and it seems there should be enough movement to disengage the clutch. My experience from cars is that when the clutch plate is worn out, the transmission slips. This is the opposite in that it doesn't seem to disengage, so what the heck is going on?

1. The leak appears to be on the left side where the rear axle carrier meets the differential housing. I suspect it's a gasket that has failed and it's a rather steady drip but I found a few loose bolts. Anybody know the torque spec?

2.The oil I drained out of the three drains looks like cafe au lait and smells pretty foul. What is the correct oil to use to fill this? The manual I have is for the US made 424 and 444 and specs IH Hy-Tran fluid. What is the correct fluid for the British made B-434?

3. I have checked the clutch pedal height and travel and it seems there should be enough movement to disengage the clutch. My experience from cars is that when the clutch plate is worn out, the transmission slips. This is the opposite in that it doesn't seem to disengage, so what the heck is going on?