TheFarmallMan82

Member

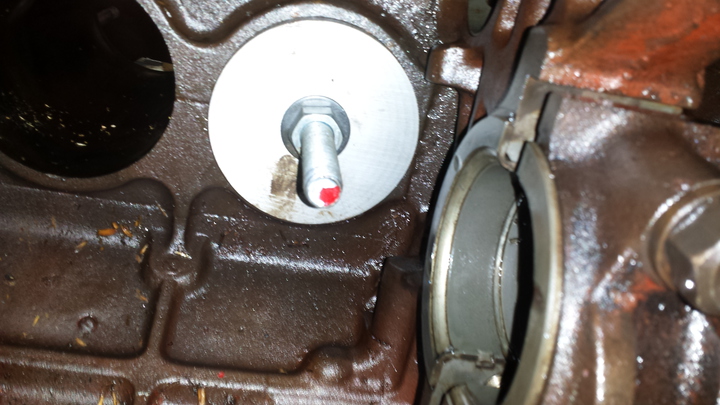

Hey all! Ive been restoring my 1928 Farmall regular and I've got it pretty much all apart with exception of the crankcase and cylinder sleeves. In the last post i had about the tractor I was trying to figure out how to pull the flywheel. Well I got it pulled with a puller I came up with using old iron from a cultivator and a 12 ton hydroponic jack. I will post some pictures of what I came up with. But right now I am having the issue with pulling sleeves. I do not have a sleeve puller or a lathe to make pucks to fit in the bottom of the sleeve. The ID and OD of the sleeves are as follows: F20/Regular-------4.110 3.740 noted from Nebraska Kirk in a previous thread. I have absolutely nothing to make these with! I have to pull them to replace the O-Rings on them and I need to replace one because its really badly pitted on the top of it and there is a very deep groove from where one of the piston rings rusted into place. If I could borrow one or have someone lend me one for a day that would be ideal. I would make them myself or have someone make them for me but I know of no one who would do it for really cheap... Anyways any help is appreciated!

Thanks guys!

Benjamin Olsufka

PS These pictures of the sleeves are before I cleaned up this area and took out the pistons to they look a lot cleaner

Thanks guys!

Benjamin Olsufka

PS These pictures of the sleeves are before I cleaned up this area and took out the pistons to they look a lot cleaner