nathanialbumpo

Member

I'm thinking of changing from a generator to a alternator on my 1971 Farmall 140, any info here on the conversion.

(quoted from post at 10:33:52 07/06/16) Easy is what I am after

(quoted from post at 20:01:37 07/31/17) .

I put in a 30A weatherpacked fuse asm, between the alternator and the battery, also from ebay./quote]

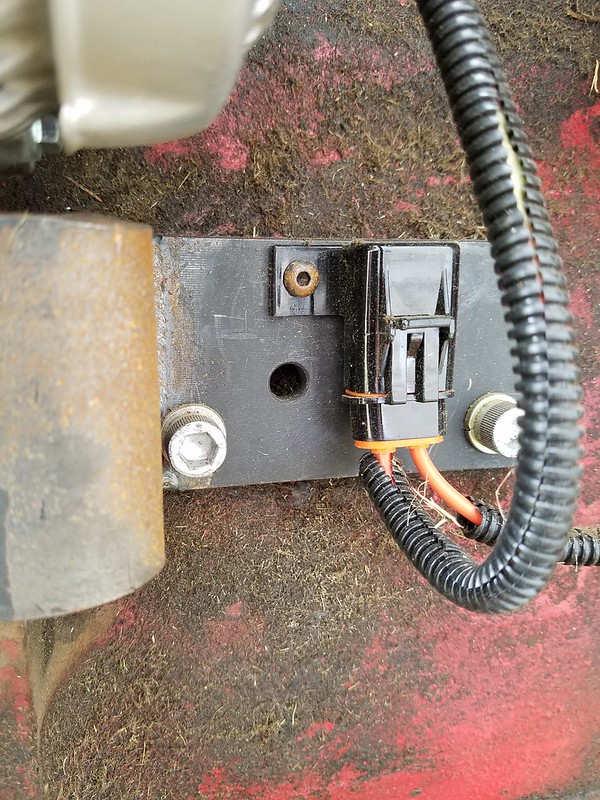

What is this?

So is a 30 amp alternator big enough. I see on Steiner's they sell the 63amp for this

(quoted from post at 09:41:00 08/22/17) Hi, sorry, I see you asked twice.

I would put it just before the ignition I have listed on the diagram.

In other words, feed the 12v to one side of the resistor. In your picture that looks like the side with the yellow butt splice.

The other side would then be dropped down to 6vdc (+/-) and you can use this to feed the ignition coil. That's the voltage it would like to work at.

Being a resistor, it should work equally well both ways, so there's no worry about being on the "wrong" terminal. 12v in, and 6v out, no matter which way you wire.

I hope this answers your question.

(quoted from post at 05:09:34 08/22/17)

How do I work this resistor into the wiring diagram?

(quoted from post at 18:44:54 09/11/17) The article I forgot to link

http://www.yesterdaystractors.com/articles/artint195.htm

The other post I found via "images"...

http://www.yesterdaystractors.com/cgi-bin/viewit.cgi?bd=ttalk&th=1055039

All good reading to understand this better.

We sell tractor parts! We have the parts you need to repair your tractor - the right parts. Our low prices and years of research make us your best choice when you need parts. Shop Online Today.

Copyright © 1997-2024 Yesterday's Tractor Co.

All Rights Reserved. Reproduction of any part of this website, including design and content, without written permission is strictly prohibited. Trade Marks and Trade Names contained and used in this Website are those of others, and are used in this Website in a descriptive sense to refer to the products of others. Use of this Web site constitutes acceptance of our User Agreement and Privacy Policy TRADEMARK DISCLAIMER: Tradenames and Trademarks referred to within Yesterday's Tractor Co. products and within the Yesterday's Tractor Co. websites are the property of their respective trademark holders. None of these trademark holders are affiliated with Yesterday's Tractor Co., our products, or our website nor are we sponsored by them. John Deere and its logos are the registered trademarks of the John Deere Corporation. Agco, Agco Allis, White, Massey Ferguson and their logos are the registered trademarks of AGCO Corporation. Case, Case-IH, Farmall, International Harvester, New Holland and their logos are registered trademarks of CNH Global N.V.

Yesterday's Tractors - Antique Tractor Headquarters

Website Accessibility Policy