Doug Kieta

Member

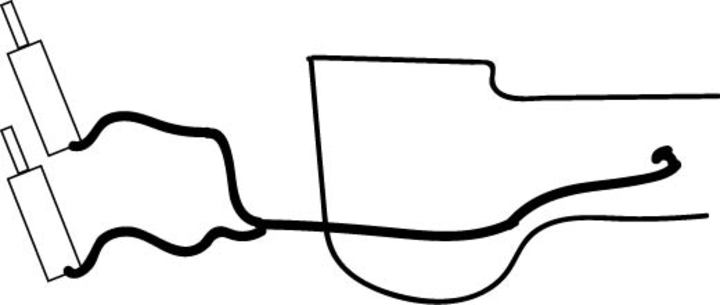

I recently posted asking how to install the hydraulic piping for a 2 cylinder 3-point adapter hitch that I am considering buying from tonystractors.com. Has anyone installed this hitch. I want to put it on a 51 H with a Liftall system. My concern is that the belly pump reservoir may be too small for operating the two lift cylinders, thus requiring installation of an aux oil tank. If you have installed it, can you either post or send me some pictures of how you mounted the valve operator and the aux oil tank if you used one, and advise the size of the tank., Pictures of the hose routings would be very useful as well.

Thanks for the help.

Thanks for the help.