Making progress, but still trying to understand why it won't fire using its starter...

When pull-starting, a higher cranking speed would generate more cylinder pressure which could help with starting. It would also advance the spark possibly in the mag.

Last night I inspected the centrifugal weights on the magneto. I turned the pin 180 degrees that they catch on when hand cranking because there was a little wear. I reinstalled the mag, checked the static timing, and tried to start it with the starter. Small puffs of white fog (looks to me like unburnt gas) came out of the exhaust pipe.

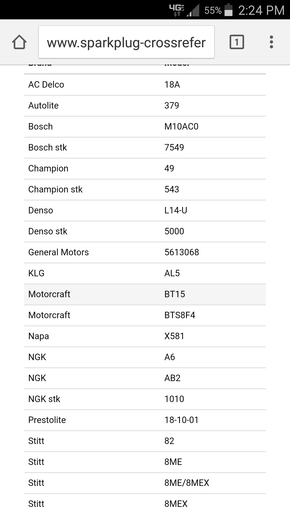

I will see if I can get a set of new Autolite 388's today and try them. I can't understand why a spark plug would function when pull starting, and when out of the head hand-cranking to check for spark and timing, but not within the cylinder head at slow cranking speeds.

Any input is appreciated!

When pull-starting, a higher cranking speed would generate more cylinder pressure which could help with starting. It would also advance the spark possibly in the mag.

Last night I inspected the centrifugal weights on the magneto. I turned the pin 180 degrees that they catch on when hand cranking because there was a little wear. I reinstalled the mag, checked the static timing, and tried to start it with the starter. Small puffs of white fog (looks to me like unburnt gas) came out of the exhaust pipe.

I will see if I can get a set of new Autolite 388's today and try them. I can't understand why a spark plug would function when pull starting, and when out of the head hand-cranking to check for spark and timing, but not within the cylinder head at slow cranking speeds.

Any input is appreciated!