Yes that is excessive. 7.2 is normal. Do you have a digital meter, or one with a needle? A digital gauge, unless it is pretty expensive, will take random samples and may not read a steady average voltage on these old systems. 4 volts is way low at the battery, I would not expect it to start. If the H has a regulator, and a 3 position light switch, the regulator may be failing. The following is from John T a GURU contributor:

Its been a while since I posted my entire Troubleshooting Procedure for non charging, so here it is.

TROUBLESHOOTING CHARGING SYSTEMS

ARE YOU SURE THE AMMETER IS WIRED CORRECT AND WORKS????? If you turn the lights or ignition on (if coil ignition not a mag) when she?s not running, the ammeter should swing over to the - discharge direction, does yours??? Are BOTH the ammeter terminals reading hot battery voltage?? They MUST !!!!!!! There?s but one wire on the ammeters Supply (from battery/starter) terminal while its other Load terminal wires to the BAT terminal on a Cutout relay or VR PLUS wires to feed loads like lights or ignition, unless where a 4 terminal VR is used where lights n ignition are fed from the LOAD terminal on the VR.

To Polarize the Generator, first temporarily dead ground the Gens Field post to case/frame, then momentarily flash jump a wire from the Cutout Relay or VR"s "BAT" terminal over to its GEN (or ARM) terminal and you ought to get a small spark. Same things accomplished by momentarily flash jumping a hot wire (BAT terminal on Cutout Relay or VR or starter post etc) direct to the Gens ARM post to get the spark.

TROUBLESHOOTING A CHARGING PROBLEM IN CLASS A DELCO TYPE SYSTEMS

1) For a good working Gen to get to and charge the battery, it has to have a path usually from the Gens ARM post,,,,,,,,,,to and through the Cutout Relay (between its GEN and BAT terminals, regardless if on a VR or Relay),,,,,,,,,up to the Load (NOT to battery) side of the Ammeter,,,,,,,,,to and through the Ammeter,,,,,,,,,,from BAT side of Ammeter to ungrounded battery terminal, often via the starter lug post. Is yours wired that way or equivalent ??? The ammeter should read hot battery voltage on BOTH terminals, does yours??? Even if an ammeter were stuck (but still continuous) as RPM increases the battery voltage should rise from 12.6 to near 14 volts and/or the lights glow brighter (half that on 6 volt systems). Have you tried that in case the ammeter isn?t working right?????

2) If the above is so, the BAT terminal on the VR or Cutout Relay MUST ALWAYS READ HOT BATTERY VOLTAGE. Does yours??? If not, the Gen cant get to and charge the battery.

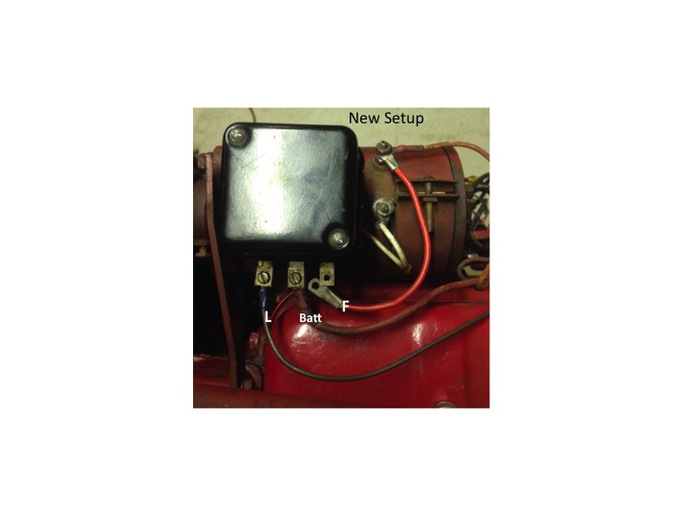

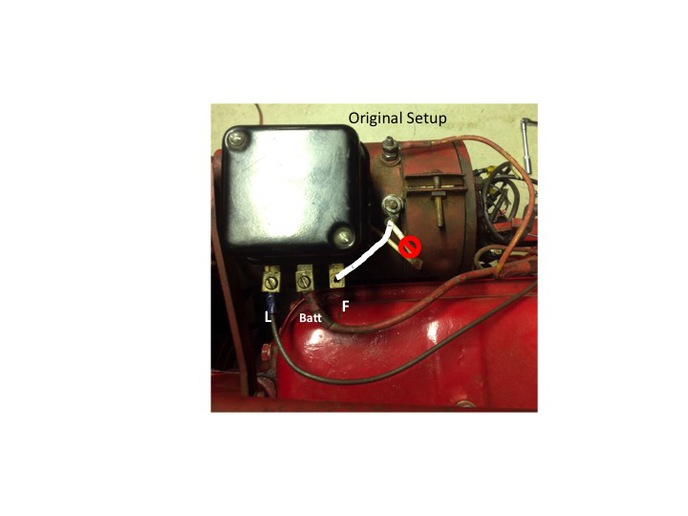

3) The Gen to VR (if it has one) wiring is as follows:

BAT on VR to ammeters load (NOT battery) side

ARM (or GEN) on VR to Gens Armature post.

FLD on VR to Gens Field post.

(L) Load (if you have a 4 wire VR) up to BAT supply input terminal on switch to feed loads like lights and ignition.

WIRING ON CUTOUT RELAYS: They wire BAT side to ammeters Load terminal,,,,,,GEN side to gens Armature post. On cutout relay systems, the Gens Field post is wired to the light switch where it gets a dead ground for high charge or a resistive ground for low charge. Therefore, there must be a good connection from the Gens Field post up to the switch PLUS the switch is good and it?s well grounded !!!!!!!!

4. THE GEN AND VR OR CUTOUT RELAY MUST BE WELL GROUNDED AND THE BELT GOOD N TIGHT. If any doubt, run a ground wire from the grounded battery post or clean solid frame member direct to the Gen and see what happens????????????????????????????

NOW, if the Gen and VR are grounded,,,,,all is wired correct,,,,,,,,BAT terminal on VR or Cutout Relay is HOT,,,,,,,,Belt is tight,,,,,,,,,Ammeter is good n continuous n works but she wont charge, have you had the batteries tested lately????? Is there electrolyte above all the plates and no cells have a gray or milky appearance?????? A bad battery may not accept a charge you know!!!!!!!! If the battery checks okay, proceed below to see if its a Gen or VR problem (AFTER you have insured the wiring per the above)

TO DETERMINE IF ITS A GEN OR VR OR CUTOUT RELAY PROBLEM

5. a) VOLTAGE REGULATOR SYSTEM: With the tractor running, temporarily ground the Gens Field post to case. If she charges then but NOT otherwise, the VR may be bad, or a wires missing from VR"s Field post to the Field terminal on the VR, or the VR isn?t well grounded.

b) IF IT?S A CUTOUT RELAY SYSTEM and she charges only if you dead ground the Field but NOT otherwise, its either a bad switch or the switch isn?t well grounded or else the wires bad or open from the Gens Field post up to the switch. INSURE THAT GOOD SWITCH GROUND AND WIRING

6. If she still don?t charge, leave the Field grounded and jump a wire across from the VR or Cutout Relays BAT terminal over to its GEN terminal (jump by passes the cutout relay) and see if she charges. If then but not otherwise, a VR"s cutout relay isn?t working correct (maybe points burned/carboned) or a Cutout Relays NOT working or not wired correct.

7. With the 2 steps above, you have basically by passed the VR or Cutout relays functions, so if she still don?t charge, you"re left with a bad battery or wiring or the Gen itself.

8. MOTOR TEST. You can Motor test the Gen. If its grounded and you remove the belt and apply hot battery voltage direct to its ARM Post and have the Field Post dead grounded to frame, it should motor n run well (Armature n Brushes and Commutator likely okay). Then, if you next remove the Fields ground and it speeds up some, the Fields probably good. If it passes both those tests, it should charge, and if not, it may be a wiring or battery or grounding problem. The hot battery voltage may be taken off the VR"s BAT terminal or the starter post or the battery itself for this test.

9. Typical Gen problems may be the brushes are worn down or the hold down spring assemblies are stuck/corroded/dirty and arent pushing the brushes tight down against the commutator. Check those things out. Worse may be bad fields or armature etc. Air and WD 40 etc can clean and free them, the hold downs must be free n snap and hold the brushes DOWN TIGHT and they cant be worn down too low.

SUMMARY: Check the wiring,,,,,the grounds,,,,,,insure BAT on VR or Relay is hot,,,,,,,check battery (maybe load tested and Specific Gravity checked),,,,,,,,,good tight belt,,,,,,,insure ammeter is continuous (BOTH sides HOT),,,,,,see if battery voltage rises above 12.6 (half that for 6 volt system) and/or light glow brighter,,,,,,,,,do the Field and cutout relay VR by pass checks,,,,,,,,insure the Gens brushes arent worn down and the hold down springs are free n clean and push the brushes down tight,,,,,,,,,,,check the connections,,,,,,,,,try the Gen Motor Test to see if its good.

You may just have a bad battery or bad ground or connection if the Gen and VR or relay are okay. Good Luck n God Bless, let us all know.

John T Nordhoff in Indiana, retired electrical engineer who usually lurks over on the Mother Deere pages instead of over here on the "dark side" lol