I missed a chance at one a few years ago and its been chafing me ever since. Found a real nice one recently and just got it home.

It even came with the operators and service manual and the alemite grease can.

The previous owner thought it might be stuck - but said they put oil in each cylinder when they found that a storm had blown the can off the exhaust.

Whats the best way to try and turn the main engine over to see? Or should I just scope the cylinders first??

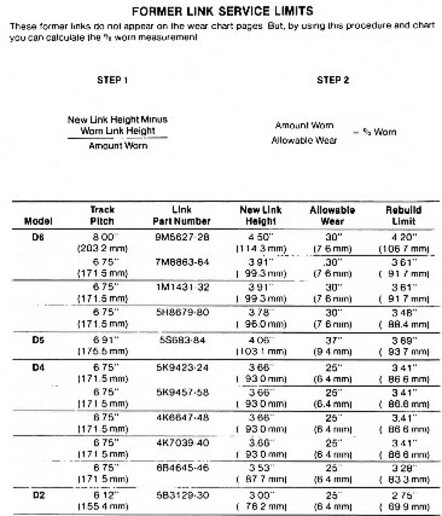

I grew up on a farm, but dont know that much about crawlers. What percentage of life do these tracks appear to have left??

Thanks for any advice,

Howard

It even came with the operators and service manual and the alemite grease can.

The previous owner thought it might be stuck - but said they put oil in each cylinder when they found that a storm had blown the can off the exhaust.

Whats the best way to try and turn the main engine over to see? Or should I just scope the cylinders first??

I grew up on a farm, but dont know that much about crawlers. What percentage of life do these tracks appear to have left??

Thanks for any advice,

Howard