mike clifford

Member

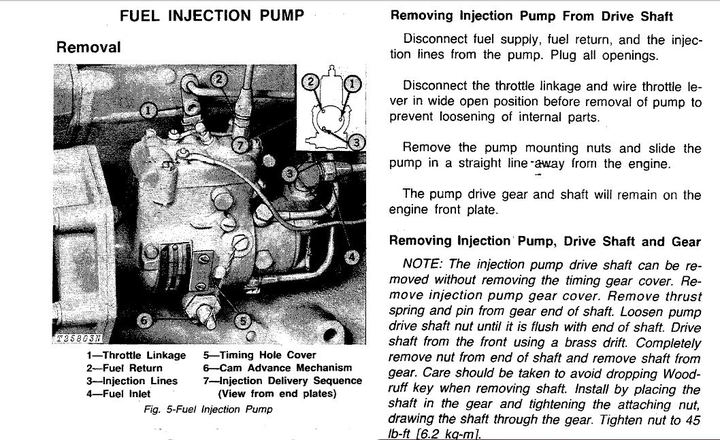

Hello I have got my dozer inside and the injection pump removed.

It is a CBC 431. 3dg. Attached is a pic of the shaft that sticks out from the timing gear area.

Is the conversion pump supposed to fit to this ? Or is this shaft to be removed? Does this look normal?

The conversion pump I saw at the dealer won't connect to this .

Also the 2 blolts that hold this pump on are much farther apart than the new pump, I know there is a couple clamps in the conversion kit, is what they are for?

J D says the instruction sheet for the adapter kit is no longer available! What's the chance you would have such a document?

Any help would be appreciated

Thank you

mc

It is a CBC 431. 3dg. Attached is a pic of the shaft that sticks out from the timing gear area.

Is the conversion pump supposed to fit to this ? Or is this shaft to be removed? Does this look normal?

The conversion pump I saw at the dealer won't connect to this .

Also the 2 blolts that hold this pump on are much farther apart than the new pump, I know there is a couple clamps in the conversion kit, is what they are for?

J D says the instruction sheet for the adapter kit is no longer available! What's the chance you would have such a document?

Any help would be appreciated

Thank you

mc