Kevin Wright

New User

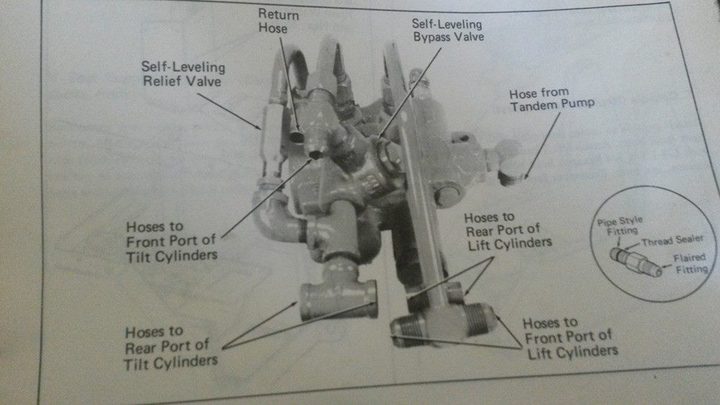

I have a Gehl HL4400 skid loader and was wondering if anyone has had any ideas on why the bucket has no lifting power to curl the bucket. It has a set of forks on it right now i was carrying freezer panels to load on a trailer when i went to pick up another stack when i went to lift the forks and they were just droopy...lift is fine and when you roll the forks down it will lift the front of the machine off the ground but it wont pick them up off the ground. I have swapped out the self leveling bypass valve, and the self leveling relief valve, from a parts machine, even changed the entire spool valve and the problem does not change. Still no up on the bucket. The whole time I have had this machine the bucket drifts down and the shop manual directs you to the self leveling valves so i have a sneaking suspension that's where my trouble is but i just cant believe two machines have the same bad valve. any ideas will be much appreciated! im fixing to light a match and walk away....