You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Thread starter Ande

- Start date

Case Nutty 1660

Well-known Member

a early model,, and another who does not know how to install the chopper drive belts,, if I am seeing it right they have a twist in the front but not the rear belt making the chopper run,, Backwards

John Saeli

Well-known Member

Brings back fond memories. Looks to be well cared for. Tom: I don't see the chopper belt on wrong. On ours, I added an idler pulley close to the drive end because once in a while, the belt would jump off. The idler stopped that. Like all I have ever seen, the rear shaker mounts broke & tore up the openings. We also fixed that problem on ours. I do not understand the "mfg. tag". What is that referring to?

Case Nutty 1660

Well-known Member

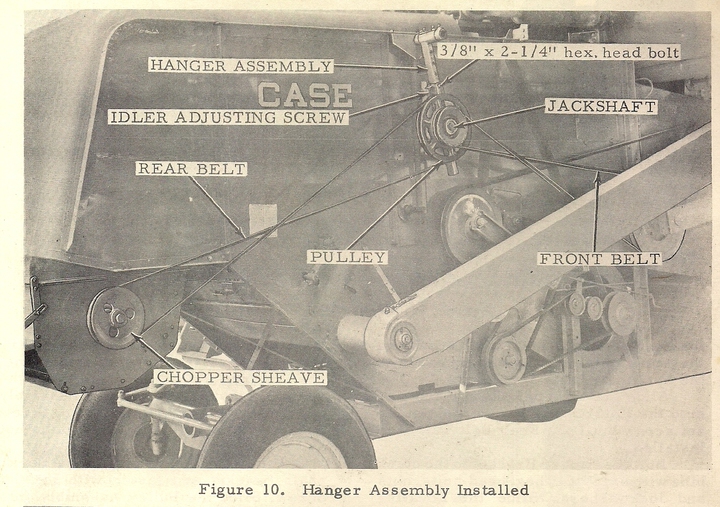

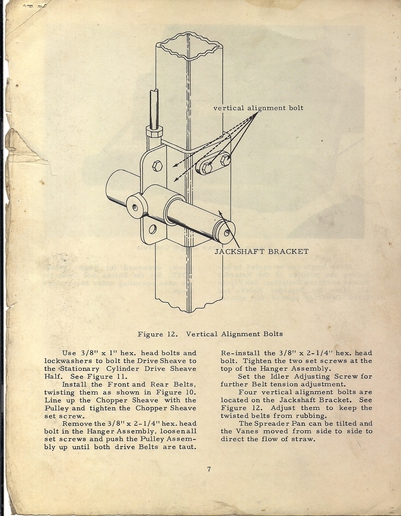

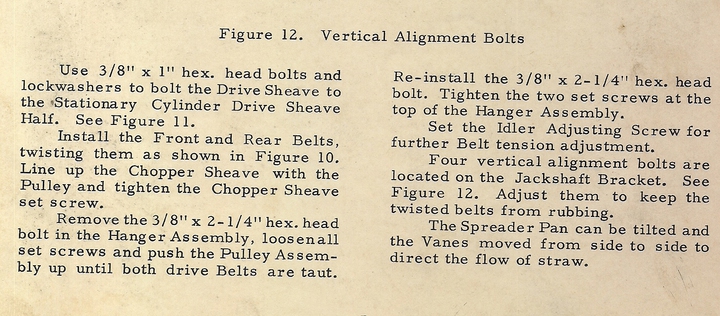

Not finding the tag you speak of yet John will look more, but I did find a pic where I see both belts are on the same and both are Wrong Always put a twist in them so they get Maximum "drive" on the pulleys,, right in the book,, yes I am am bit picky the 1160 I have the owner told me the chopper knives were junk as in green weeds it would plug all the time,, he had a twist int he front belt and not the rear the chopper turns backwards and throws the material up against the top of the straw hood I can get you picks of what it does in soybeans,, mine looks like you took a chipping hammer to the inside of the tin,, the knives were new on the correct side as they had never been used,, also had guys tells me belts would not last in heavy straw,, I say yes they burn up quick installed wrong lol I can dig out my chopper ops and show you what I mean,, that is why the idler unit can be tilted so when the belts pass each other they do not rub so hard

cnt

cnt

John Saeli

Well-known Member

I always used OEM belts, so yes, I must have had the 2 belts "crossbelt". But still, the rear belt would jump off the drive pulley, so I added an idler. BTW, I cannot find a picture of the full side with the belts installed in the op. manual, just a sectional view in the parts book.

Case Nutty 1660

Well-known Member

I have a ops for just the chopper but with me moving my stuff into my new Case room I am having a time locating it,, I never had any issues throwing belts even the 600 which has very worn narrow rolling over belts do not come off,, maybe something was out of alignment a bit?

cnt

cnt

John Saeli

Well-known Member

Probably not. But this machine looks to be real nice, but I can't see anyone buying it for production. Especially for soybeans, with the possibility of rocks damaging the combine, especially the header & auger, ect. Maybe take it to a show & run wheat thru it. Kinda like buying a real nice 50 year old long nose Pete. You'd never run it hard everyday, especially in & out of a gravel pit. Having said all that, there are guys on here still using these machines.

(reply to post at 13:57:03 08/20/18)

Hey case nutty

I don’t see the belts being wrong

I don’t cross any that I use and I don’t have any trouble

Just saying

Dugger

Case Nutty 1660

Well-known Member

Just telling you what the book says its yours do what you want

(reply to post at 11:18:55 08/20/18) [/quot

Forgot to mention I have seen that machine

Pics are old

It doesn’t look that nice now

It’s been under roof but it has rusted a lot

He had two and I bought one 2 years ago

They both had around 1600 hrs

Dugger

casecollectorsc

Well-known Member

- Location

- E central SD.

I couldn't find it either. Have run mine "straight" for 43 years and never had a problem. Guess it is a preference of the operator.

Case Nutty 1660

Well-known Member

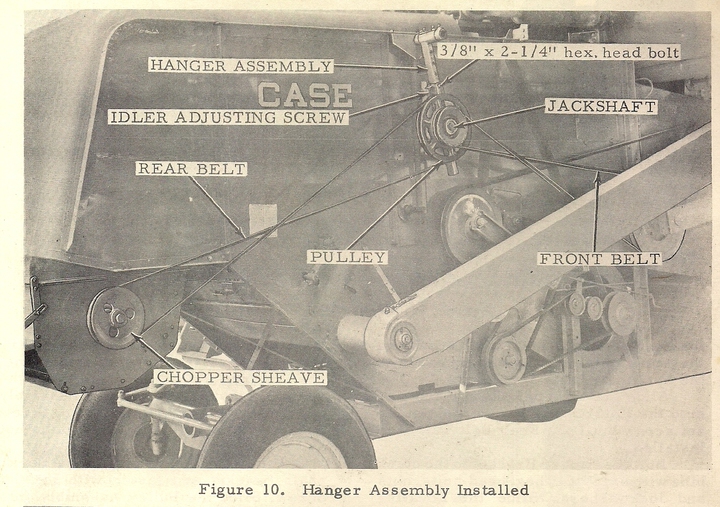

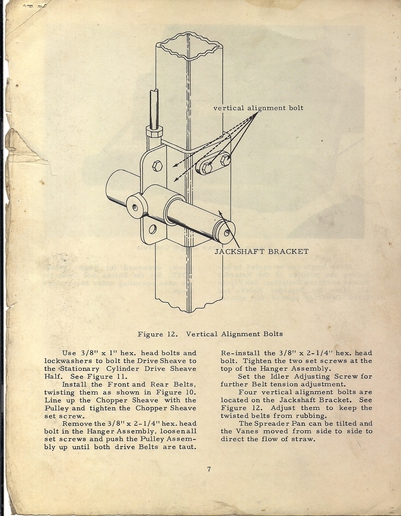

I guess setting them up by the book was just how I did things, belt life is what would be the main issue and belt jump as John found,, I also set these up new, again its right in the Innes chopper manual,, if you know about belt drives the grip on the sheaves increases 20% or more doing this,, I also worked for 10 years at a industrial supply house,, it was always recommended to twist belts if you had so much distance between sheaves, in heavy straw with any green weeds from a 19" or 20' header you want all the power to the chopper you can have or you are unplugging it and replacing belts far sooner than need be,, I worked with dealers in MT and KS a number of times, these are Big small grain areas that sold LOTS of Case combines all of us talked about the belts on incorrect,, just like those who have no clue which way to install backhoe bucket teeth, I guess its a pet pi-eve of mine, but no big deal if you never seen the idler pulley design and asked yourself why it was made the way it is to allow the belts to not rub each other when twisted,,, I guess I am far more picky than others are about things,, just me I guess,, at meetings dealers always talked about these kinds of things, I guess you had to be in our shoes to understand

(reply to post at 05:54:24 08/21/18)

I had a guy tell this yesterday

It’s yours do as you please

Haha

Good morning

Dugger

(reply to post at 09:27:18 08/21/18) [/quot

Tom I understand what you say

Here in the midwest we don’t have to do that

Our problems are keeping the knives or sections

On the chopper

Little stones knock knives off the drum

But belts are not a problem

I’m just giving you a hard time

Dugger

casecollectorsc

Well-known Member

- Location

- E central SD.

The first case combine I bought was the 1160. Belts on the chopper were shot from rubbing from being crossed. Put new ones on and ran them straight ever since on all Case machines here.

Case Nutty 1660

Well-known Member

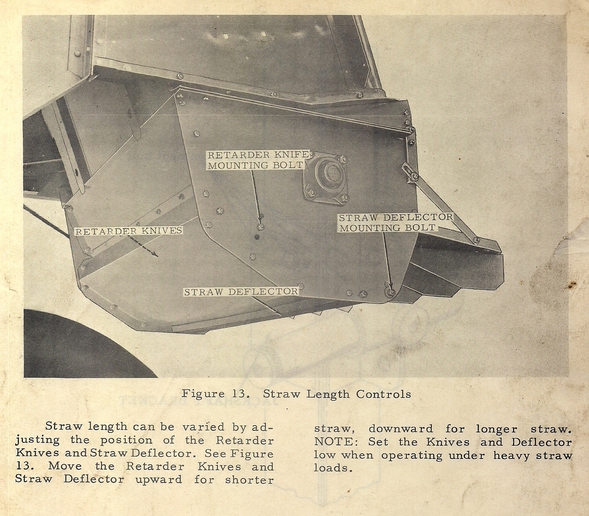

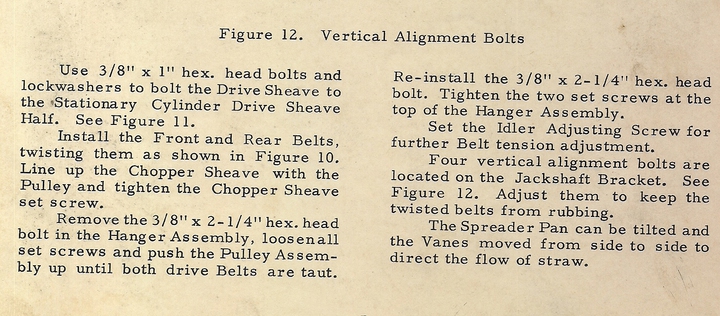

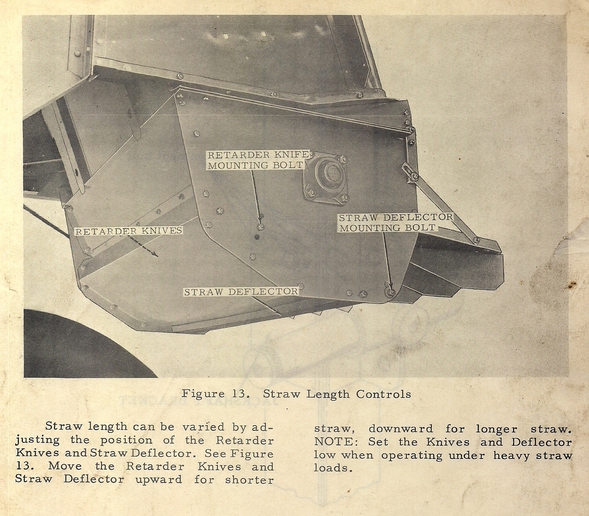

Here you go Dan,,, I added the straw length adjustment in "Case" some one did not have those instructions as well, this is for the 1010 unit but I also have the sheet for the later 60 series machines but the instructions are the same, this is the one I found first, takes a while to go through it all piece by piece lol

cnt

cnt

Case Nutty 1660

Well-known Member

I guess I am not blowing Smoke after all huh Dan? I have always went by the book on things like this,, first time I seen a chopper kit I wanted to know why the idler was made the way it was,, no reason for all the adjustments if it just tied the two belts together,, will it work with out a twist SURE it does but like I said try it with max header size and max straw intake,, belts did not last well at all,, at least here anyway, and here all I knew was to use the biggest header you could get,, if you had a bumper crop you slowed down,, we are also DRY for the most part when cutting here,,10-15% humidity and the grain has to be 13% or under or we do not cut it as we have no way to dry it out here, no need for grain driers,, the man I bought my 1160 flat out said the chopper was junk,,( it came from Appleton MN) he stopped by a year later on vacation and seen it running wheat, chopper working beautifully and said Wow that chopper you put on works GREAT! I said well its the same one O bought from you but its running the right direction now,, he said in the 20 years he owned it it never worked anything like that and I had a 18' header on it where he ran a 14,, I have a nickname here with certain folks,, "Tommy Tunes" I will let you decide what it means lol

cnt

cnt

Ande

Well-known Member

Exactly Tom, I knew you had your ducks in a row, and also another reason, as I put the belt on myself once when I was young, and my Dad told me you have the chopper running backwards, and he took the time to explain to me why it needed the twist.

I have found your advise and ideas good for me to follow.

I have found your advise and ideas good for me to follow.

(reply to post at 07:07:55 08/22/18)

Tom

I’m sure you know more than I do about case

Machines

Im an infant on those

But remember when you tried to tell me my hub and sprocket were two pieces

Well it isn’t

Haha have a wonderful day

I do learn from you so keep up the good work

Dugger

Case Nutty 1660

Well-known Member

Production changes to them happened a lot I do not know everyone. sorry for the misinformation, I am not saying I know everything about them any way shape of form,, there are still options and accessories I have yet to deal with,, I will refrain from commenting on these posts from now on

cnt

cnt

(reply to post at 07:43:52 08/22/18)

Tom

Please don’t quit commenting

We value your knowledge

I really do learn from you

But we all need to remember we are not perfect

I need people like you to remind me too

We need to get together sometime

Thanks again

Dugger

(reply to post at 17:53:53 08/23/18)

I went to look at them in 2015

I did not see a hitch on them so he must have taken it off

Dugger

Similar threads

- Replies

- 3

- Views

- 286

We sell tractor parts! We have the parts you need to repair your tractor - the right parts. Our low prices and years of research make us your best choice when you need parts. Shop Online Today.

Copyright © 1997-2024 Yesterday's Tractor Co.

All Rights Reserved. Reproduction of any part of this website, including design and content, without written permission is strictly prohibited. Trade Marks and Trade Names contained and used in this Website are those of others, and are used in this Website in a descriptive sense to refer to the products of others. Use of this Web site constitutes acceptance of our User Agreement and Privacy Policy TRADEMARK DISCLAIMER: Tradenames and Trademarks referred to within Yesterday's Tractor Co. products and within the Yesterday's Tractor Co. websites are the property of their respective trademark holders. None of these trademark holders are affiliated with Yesterday's Tractor Co., our products, or our website nor are we sponsored by them. John Deere and its logos are the registered trademarks of the John Deere Corporation. Agco, Agco Allis, White, Massey Ferguson and their logos are the registered trademarks of AGCO Corporation. Case, Case-IH, Farmall, International Harvester, New Holland and their logos are registered trademarks of CNH Global N.V.

Yesterday's Tractors - Antique Tractor Headquarters

Website Accessibility Policy