Ken Christopherson

Well-known Member

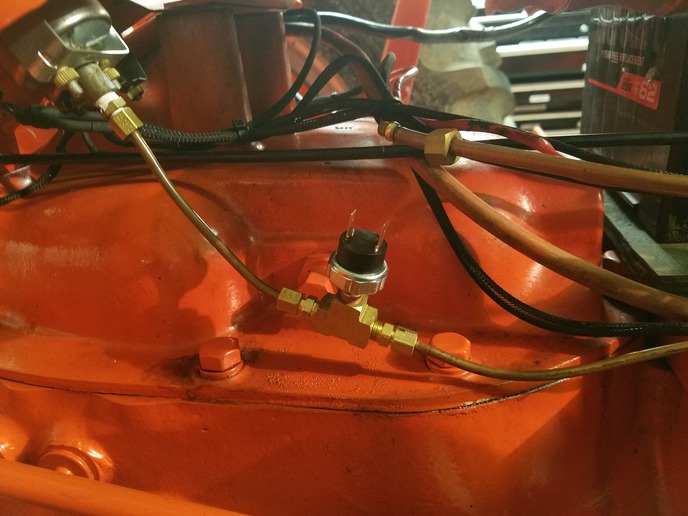

Hello all! Well, I am working on converting all of my tractors over to 12 volt with alternator. Farmall M, H, and John Deere A should be easy. My Case SC, however seems to prove a little more difficult as for as mounting goes. Here are my questions:

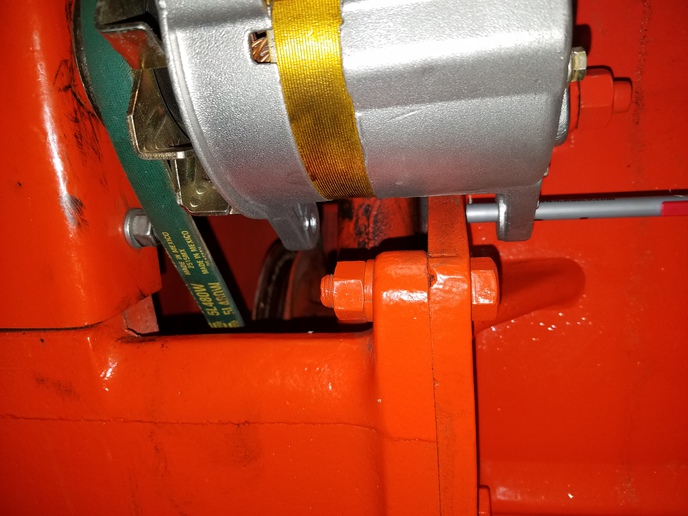

I picked up 2 Hitachi 14231 alternators as it is smaller and not as 'bulky' as the Delco 10SI (which I have two of, one for my M and one for my JD A). Plan to put the Hitachi on the Farmall H and Case SC. Delco 10SI will go on the JD A and IH M. Here are my options or plan of attack at mounting the alternator on the Case:

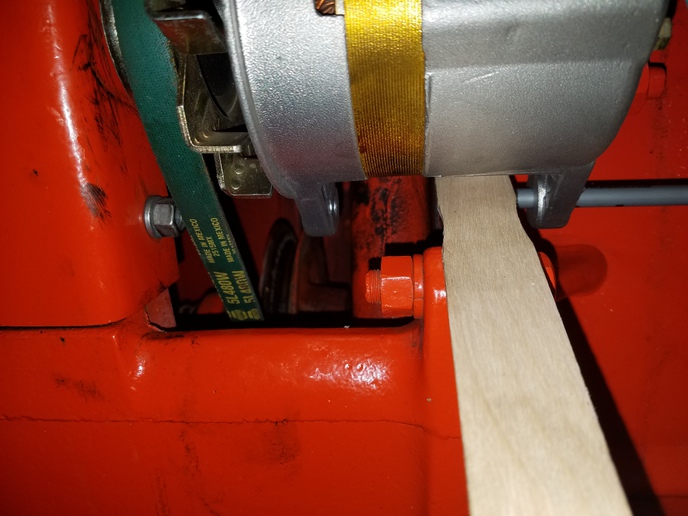

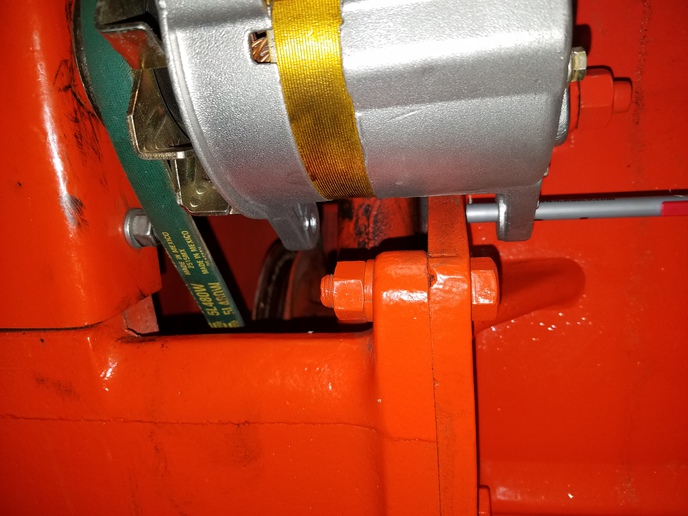

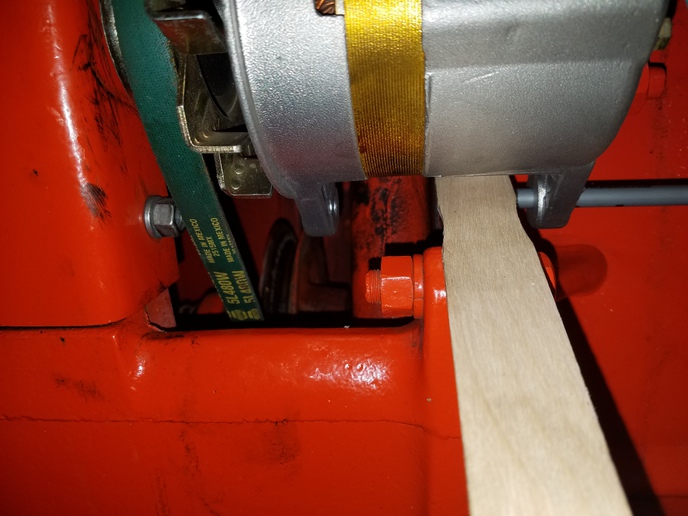

Option 1) Drill a 3/8 hole through the front flange of the engine block (See photo of screwdriver pointing to marked location, and mock-up placement of alternator). This would leave approximately 1/4" of material left above the hole. I would then mount the alternator using a 3/8" shoulder bolt with sleeve spacers to obtain the correct spacing. The top adjustment bracket would still be used in the factory location (although I would have to make a new one). My only concern is will I risk the front flange of the block cracking through this drilled hole? The tractor doesn't get heavy use - mostly just threshing shows and may get occasional yard chores at our next property.

Option 2) Remove the rear-most tab on the bottom side of the alternator (possibly compromising the strength of the front tab). Mount in the factory generator location. My concern here is the bottom front tab, if it is the only mounting point, will eventually crack or break due to both vibration and the amount of weight that is being held by just the single bottom tab.

Option 3) Mount the alternator in the factory generator location, but this would involve having someone fabricate a custom bottom bracket (as I do not have a welder). This is probably the most secure method, but would be quite involved. I don't have easy access to equipment to do this.

What are your thoughts on this? Would I be better to use a Delco 10SI? It seems that this alternator fits nicely, it is just the mounting that is giving me concerns. (I can always use the Hitachi on the IH M, and a Delco on my Case).

I picked up 2 Hitachi 14231 alternators as it is smaller and not as 'bulky' as the Delco 10SI (which I have two of, one for my M and one for my JD A). Plan to put the Hitachi on the Farmall H and Case SC. Delco 10SI will go on the JD A and IH M. Here are my options or plan of attack at mounting the alternator on the Case:

Option 1) Drill a 3/8 hole through the front flange of the engine block (See photo of screwdriver pointing to marked location, and mock-up placement of alternator). This would leave approximately 1/4" of material left above the hole. I would then mount the alternator using a 3/8" shoulder bolt with sleeve spacers to obtain the correct spacing. The top adjustment bracket would still be used in the factory location (although I would have to make a new one). My only concern is will I risk the front flange of the block cracking through this drilled hole? The tractor doesn't get heavy use - mostly just threshing shows and may get occasional yard chores at our next property.

Option 2) Remove the rear-most tab on the bottom side of the alternator (possibly compromising the strength of the front tab). Mount in the factory generator location. My concern here is the bottom front tab, if it is the only mounting point, will eventually crack or break due to both vibration and the amount of weight that is being held by just the single bottom tab.

Option 3) Mount the alternator in the factory generator location, but this would involve having someone fabricate a custom bottom bracket (as I do not have a welder). This is probably the most secure method, but would be quite involved. I don't have easy access to equipment to do this.

What are your thoughts on this? Would I be better to use a Delco 10SI? It seems that this alternator fits nicely, it is just the mounting that is giving me concerns. (I can always use the Hitachi on the IH M, and a Delco on my Case).