munson1086

Member

Hi everyone,

I know this is a topic that has been hit on in the past, but I still cant seem to find an answer.

Lately my clutch seems to not be releasing all the way. At first I thought it was a pulley brake issue. After adjusting, the brake just seems to burn, without stopping. I can still shift in gear, it just grinds really bad. Once in gear, the clutch works, you just have to shift really quick to avoid grinding.

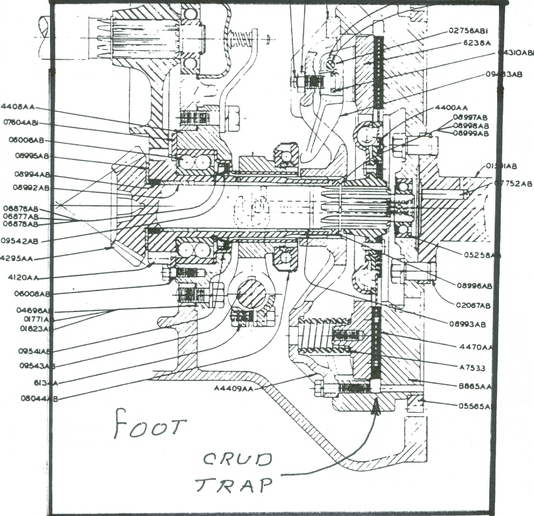

The only time I could get the clutch to work better was to adjust out the link on the foot clutch - way past what is described in the Case procedure. I'm just worried if the arm is adjusted out so much, the clutch will slip. With the lack of availability for these clutch parts - I don't want to do that!

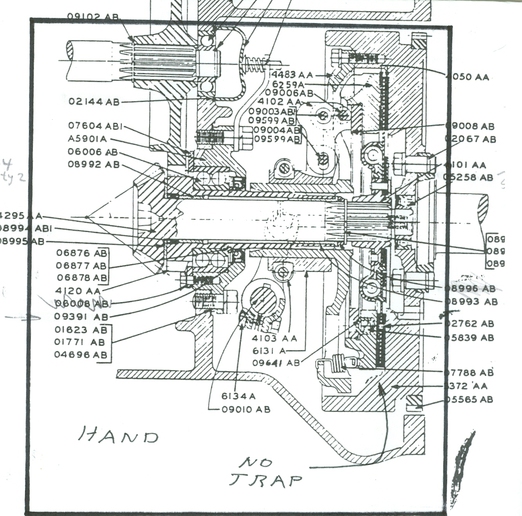

I have read some posts about adjusting the 'fingers' - but in all my manuals, not one mentions this. The newest manual I have focuses on live power/hand clutch. How does one go about adjusting the fingers?

I hope my rambling makes sense. Any help is appreciated!!

Matt

I know this is a topic that has been hit on in the past, but I still cant seem to find an answer.

Lately my clutch seems to not be releasing all the way. At first I thought it was a pulley brake issue. After adjusting, the brake just seems to burn, without stopping. I can still shift in gear, it just grinds really bad. Once in gear, the clutch works, you just have to shift really quick to avoid grinding.

The only time I could get the clutch to work better was to adjust out the link on the foot clutch - way past what is described in the Case procedure. I'm just worried if the arm is adjusted out so much, the clutch will slip. With the lack of availability for these clutch parts - I don't want to do that!

I have read some posts about adjusting the 'fingers' - but in all my manuals, not one mentions this. The newest manual I have focuses on live power/hand clutch. How does one go about adjusting the fingers?

I hope my rambling makes sense. Any help is appreciated!!

Matt